Shielded Mild Detonating Cord

Product Description

Shielded Mild Detonating Cord is an explosive transfer line providing a communications link within an explosive system while containing any bi-products within its sheathing material. When it comes to shielded mild detonating cord, you don’t just need rapid products to initiate charges simultaneously, you want to protect the surrounding areas from any bi-products produced during the explosive train.

Key Features

We manufacture SMDC Shielded Mild Detonating Cord sheathed in a variety of materials to help you reliably operate in high-pressure, high-temperature environments. Our SMDC is typically drawn or extruded into a round configuration and can be rolled into an elliptical or flat ribbon shape to support your complex needs.

Hexanitrostilbene (HNS) versions of our SMDC can withstand temperatures up to 500°F for 50 hours. Our detonating cords can be further sheathed in metal tubes to contain fragments and operate in high-pressure environments (30,000 PSI).

How Shielded Mild Detonating Cord Works

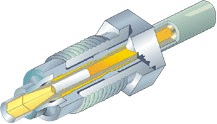

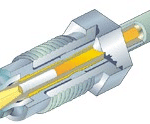

Shielded Mild Detonating Cord assemblies are explosive transfer lines, consisting of a metal sheathed explosive core, covered with an extrusion, all contained within a thin wall stainless steel tube. The Mild Detonating Cord (MDC) most commonly used in SMDC is a high temperature explosive which allows the MDC to withstand temperatures in excess of +425oF for short periods of time without any detrimental effect on the detonation characteristics.

Functions

SMDC provides reliable detonation signal propagation from one point to another while containing the detonation by-products. The SMDC lines can be arranged in various systems with the use of manifolds and other energetic components (one ways, time delays, and / or gates) to provide a self-contained energetic transmission system that can accomplish specific mission applications such as fracturing/severance, egress of aircrew, structural cutting, rocket stage separation, destruct sequences to terminate flight and operation / initiation of energetic devices. Containment of the detonation products allows for the system to be used in close proximity to personnel and to systems that are sensitive to contamination such as optics.

Explosive functions during emergency egress of an SMDC line include operating emergency oxygen valves, actuating cable cutters, igniting rocket motors, activating shaped charges and deploying parachutes.

Specifications

- Hermetic Seal

≤ 10-5 cc/sec (air) - Humidity

100% of water or frost - Withstanding Pressure

Operate in complete vacuum or under water to the tubing crush strength - Storage Temperature

-80°F to +200°F - Operating Temperature

-65°F to +350°F, will withstand 425°F for periods of 5 minutes - Vibration

80 to 2000 cps +/- 20G - Shock

3 shocks of 40G in any direction - Acceleration

40G in any direction - Drop Test

6 foot drop – operational

40 foot drop – safe to handle - Plate Dent Test

0.010 inch minimum dent depth in steel plate

0.040 inch minimum dent depth in aluminum plate - Initiation

No. 6 Blasting Cap or various qualified devices available through PacSci EMC (Arm Fire Initiators, Lanyard Pull Initiators, Electrical Detonators, EFIs, Safe Arm Devices) - Transfer Gap

0.02 inch to 0.10 inch, tip to tip

FAQ's

-

What are shielded mild detonating cords used for?

PacSci EMC Shielded Mild Detonating Cord designs are qualified and used extensively on multiple military aircraft platforms including: F-18, F-18A, F-15, F-14, AH-1, B-1, and B-1B. In addition PacSci SMDC designs are used for stage separation on Delta IV launch vehicle and on missile platforms.

-

How are shielded mild detonating cords made?

Our shielded mild detonating cords consist of a metal sheathed explosive core, covered with an extrusion, all contained within a thin wall stainless steel tube.