Electronic Safe and Arm Device

Product Description

An Electronic Safe and Arm Device (ESAD) provides safety critical energetic systems initiation on command, when commanded for flight termination, solid rocket motors, warheads etc. Designed for applications where a reliable arming and firing sequence with precise timing events is vital. Used for flight termination systems and rocket motor ignition, our ESADs meet the stringent requirements of RCC-319 and MIL-STD-1901A.

Utilized with our Bulk Destruct Charge or Linear Shaped Charge, our fully electronic device interfaces with a flight termination receiver, or mission controller, through a customizable input connector. This device outputs a high voltage firing current to initiate single or dual Low Energy Exploding Foil Initiators (LEEFIs). Our ESADs can be integral with the LEEFI energetic output or can initiate the LEEFIs through a high voltage flex tip. Also referred to as a high-energy electronic initiator firing unit, this device meets safety board requirements by incorporating two unique inhibits that must be satisfied prior to firing. Both “armed on the ground” and “armed after safe separation” approved variants are available.

Key Features

- Qualified to RCC-319 for Flight Termination on many US ranges and with many US safety boards. (FISTRP, ISSRB, WSESRB, AFSRB)

- Compatible with MIL-STD-1901A, MIL-STD-1911A, MIL-STD-1316F Qualified to MIL-STD-461 for EMI/EMC.

- Customizable safety logic, safe separation timers, break wires, acceleration set points, and I/O configurations

- Compatible with industry standard Flight Termination Receivers (FTR) or Autonomous Flight Termination Units (AFTU)

- Rugged, hermetically sealed construction for high altitude or space applications

- Laser welded hermetic 304L stainless package

- Many mechanical packaging options

- High dynamic and thermal environmental qualification heritage

- High Voltage Low Energy Exploding Foil Initiators

- Single or Dual Outputs

- 2 static and 1 dynamic switch

- Internal redundant bleed resistors

- Power on self test and arm status outputs

- Actel Antifuze Mil Spec FPGA

- Reverse bias protected input and output pins

- Proper sequence and signal filtering

- Built in hardware timers for safe separation

- (Range of Timing)

- Several available external inhibit inputs

Benefits

There are several design benefits including:

- 2-3x reduction in size and weight compared to Electromechanical Safe and Arms

- Cheaper than Laser Safe and Arms

- Flexible

- Modular features and inhibits

- HV Safe and Arms do not include verification of the EFI bridge

- Smaller and lighter than Electromechanical SADs (2-3x)

- HV SADs are more customizable

- Internal FPGA allows for more system logic states, unique behavior and control and has modular features than can be added or removed

- Accelerometers

- G switches for launch or impact detection

- Temperature/pressure sensors

- Keep alive capacitors to weight by eliminating FTS batteries

- Single or multi output

- Built in digital timing

- Power on self test (POST)

How are Electronic SADS used?

This is the only Safe and Arm Device (SAD) considered to be an “In-Line” SAD. Sandia developed an enabling technology in the 90s called an “Exploding Foil Initiator” which does not depend on heat to ignite the pyrotechnic. Instead it uses an insensitive secondary explosive which is directly initiated with a high velocity detonation impact. The high velocity flyer is generated by discharging very high current (>1000A) through a small reactive semiconductor which then explodes and propels a tiny flyer at velocities greater the 3000m/s into the explosive pellet. Due to the insensitivity of this technology and the very specific electrical impulse required to fire it the US safety board community allowed for the use of an all electronic firing system without the need for mechanical/physical barriers.

Arming requires 3 MOSFETs to close to charge the high voltage capacitor.

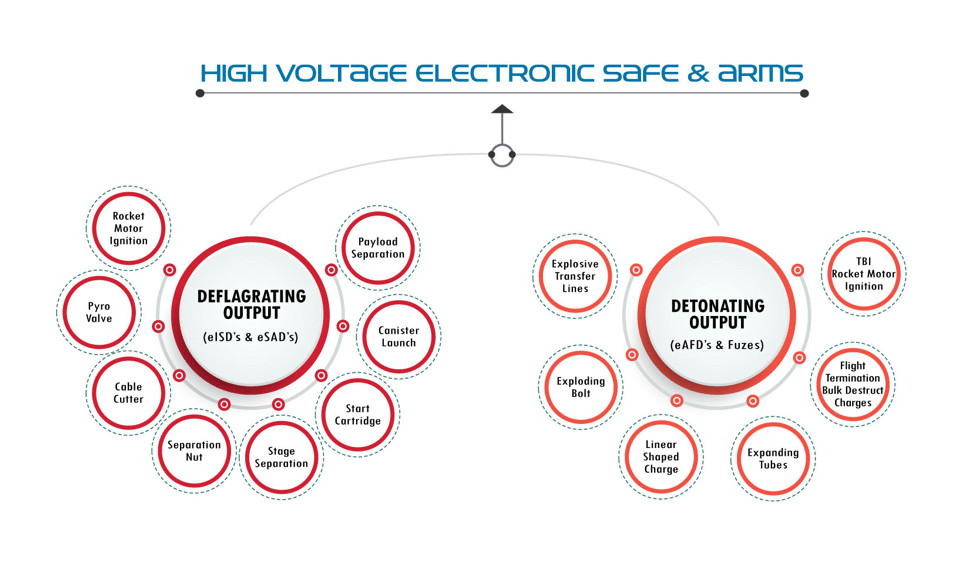

The most recent pyro-technology type is the High Voltage Electronic Safe and Arm Device (HV SAD).

Unlike all other safe and arm devices, it is an inline safe and arm, meaning, there is no physical block between the firing energy and the output pyrotechnic device. The output pyrotechnics for a HV SAD is an exploding foil initiator.

For a high voltage safe and arm system to be considered a safety system, there are few requirements it must meet. It can only utilize insensitive secondary explosives. These are listed in MIL-STD-1316. And its initiator must require greater than 500 volts DC for initiation of the output. The two requirements are achieved by using what we call an exploding foil initiator (EFI). And the EFI is the fundamental enabling technology for the high voltage, safe and arm.

Sandia developed this enabling technology in the 90s, which does not depend on heat to ignite the pyrotechnic. Instead it uses an insensitive secondary explosive which is directly initiated with a high velocity detonation impact. The high velocity flyer is generated by discharging very high current (>1000A) through a small reactive semiconductor which then explodes and propels a tiny flyer at velocities greater the 3000m/s into the explosive pellet. Due to the insensitivity of this technology and the very specific electrical impulse required to fire it, the U.S. Safety Board community allowed for the use of an all-electronic firing system without the need for mechanical/physical barriers. Arming requires 3 MOSFETs to close in order to charge the high voltage capacitor:

- Two Static

- One Dynamic

Flight Termination Electronic Safe & Arm Device (FTS ESAD)

As a leader in the design, test and manufacturing of Safe and Arm devices, our Electronic Safe and Arm Devices (ESAD) and detonators for safe compliant requirements of both legacy and next-generation IM-compliant munitions. Our talented team of scientists and engineers use the latest advances in technology to design meet harsh launched weapon systems requirements. Count on our shock-hardened designs, proven to survive and function post launch. We include options for multipoint initiation configurations while also designing for proximity, impact, and timed self-destruct detonation. All of our ESADs are manufactured in a state-of-the art ISO 9001 facility.

Description

The FTS ESAD is a single or dual output high voltage flight termination safe and arm which initiates exploding foil initiators (EFI) after the receipt of all valid arming and firing conditions.

Input Connector

The input connector is a MIL-DTL-83513 female Micro-D with either a 51 pin or 21 pin configuration depending on the required number of inputs and telemetry outputs. The pin out configurations are shown below with an example of the 21 pin signal assignments.

Out Connector

The output connector is a glass to metal hermetic high voltage 2 pin bulk head design which mates with a low inductance HV flex circuit in order to interface with a detonating EFI.

Applications

Configurations

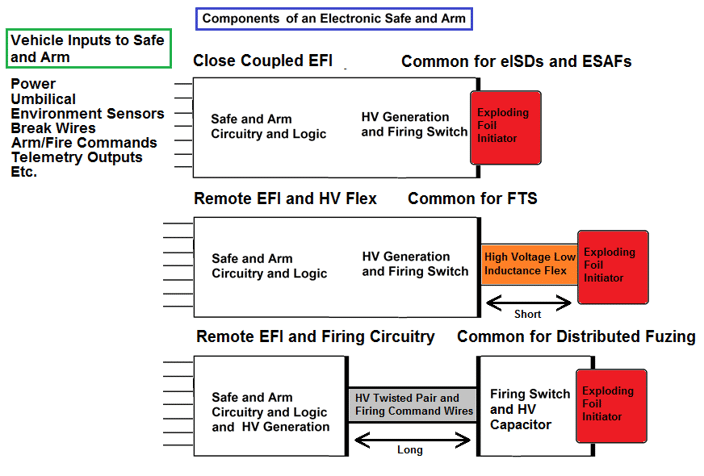

All the device nomenclatures listed below are “In-Line” electronic safe and arms which utilize high voltage EFI technology. On the left is a list of acronyms to help clarify some of the confusion around the naming of these devices. All HV safe and arms use very similar internal circuitry and logic but tend to have different acronyms assigned based on what function they are performing. There are three common ways the safe and arm can be configured.

#1. Close coupled EFI system. This should be a single package that has the safe and arm circuitry and logic, the high voltage generation circuitry and the firing switch all co-located in a single package. The EFI is either directly mated with are welded into that package.

#2. Remote EFI and high voltage flex configuration. This has a single unit which contains the safe in our logic, the safe and arm circuitry, the high voltage generation, and the firing switch. But the EFI is now connectorized and in place on the end of a strip line. These are a special configuration because the fire pulse passes through the strip line and the inductance and losses in that strip line must be considered, thus the distance must be kept as short as possible. These types of devices are common in a flight termination system where the exporting furniture can be detached up to 12 inches from the safe and arm.

#3 Remote EFI and firing circuitry. More common for the distributed fusing systems, where the inductance and the short distance is not a concern. In this case, the Safe and Arm contains the safe and arm logic, the safe and arm circuitry, and the high voltage generation. We move the firing switch and the high voltage capacitor to a remote location with the EFI. We can connect those with a simple high voltage twisted pair. In this configuration, the EFI is moved much further away from the safe and arm logic.

All the device nomenclatures listed below are “In-Line” electronic safe and arms which utilize high voltage EFI technology. This list of acronyms can be confusing due to their similarity. To better understand each one, please see below. The high voltage portions use very similar internal circuitry and logic, but the devices tend to have a different acronym used to define them based on the function they perform. Even though all the systems are very similar, if it’s being used for rocket motor ignition, its often called an EISD. If its used for fuzing, it’s often called an Electronic Safe and Arm Fuze (ESAF). If its a Flight termination system, or a hand-emplaced ordnance system, it is sometimes called an Electronic Safe and Arm Device (ESAD) or Electronic Arm Fire Device (EAFD). Essentially, they’re all variations of the same thing, simply different acronyms based on the system in which they are being used.

Acronyms

- eISD/EISD – Electronic Ignition Safety Device

- eSAD/ESAD – Electronic Safe and Arm Device

- eSAF/ESAF – Electronic Safe and Arm Fuze

- eAFD/EAFD – Electronic Arm Fire Device

Three Common Implementations

There are also serval ways to implement a HV SAD in a system and each is convenient for different reasons

Specifications

Electrical Characteristics

Logic power

Wide voltage input range options 5v – 36v

Arming power

Internal regulation of power inputs for logic and arming circuits

Power requirements

Pre-Armed quiescent current <70mA

Arming peak current variable from (100mA @ 100ms arming time) to (1.2A @ 10ms arming time)

Post-Armed quiescent current <100mA

Two static switches & one dynamic switch:

• Factory selectable separation timers

• Accelerometers

• Breakwire (umbilical disconnect)

• Event sequence and timeout

• Flight battery switch detection

• Additional custom configurations available

Specification Questions

Question: What is a Safe and Arm Device?

Answer: A Safe and Arm Device (SAD) controls the initiation of a pyrotechnic device such that the energetic output is fired only when commanded and is safe at all other times. It’s a device that prevents inadvertent arming or firing of a pyrotechnic event and makes the system is insensitive to environmental stimulus, such as fires, electro-magnetic fields, stray voltages and electro-static discharge.

Question: What does ESAD mean?

Answer: Electronic Safe and Arm Device.

Question: How does an ESAD work?

Answer: An Electronic Safe and Arm Device uses an insensitive secondary explosive which is directly initiated with a high velocity detonation impact. The high velocity flyer is generated by discharging very high current (>1000A) through a small reactive semiconductor which then explodes and propels a tiny flyer at velocities greater the 3000m/s into the explosive pellet.

Question: Can you provide an LEEFI?

Answer: Yes, we manufacture LEEFIs and also work closely with other LEEFI manufactures to provide the complete safety system.

Question: Can I buy one off the shelf?

Answer: Possibly, if your program is able to adapt to the features of an existing design. If not our modular design approach allows us to adapt to your program requirements while minimizing NRE.

Question: Do you have a publicly available drawing?

Answer: No, each ESAD is unique to the platform on which it flies. We have a system data sheet which covers the features and functionalities available.

Questions to Consider

- What is your application, to help us understand what the device is meant to accomplish?

- Which one of our devices is closest to your application?

- Do you already know which specification applies, and what’s the platform of the vehicle?

- Do you know whether pyrotechnic output is deflagrating or detonating?

- Is it a bulk destruct charge?

- Do you require transfer lines?

- What are your envelope and power restrictions do you need to keep live batteries in this design doesn’t need to be extremely low power?

- Do you need the ability to co-locate the entire device in one area?

- Does it need to be separated in one of those other configurations?

- When is the arming occurring? Before launch or arm after launch? On a rocket motor ignition it’s always before or prior to launch. On things like fuses and FTS it is usually arm after launch and changes the types of inhibits we use.

- Do you have redundancy requirements?

- Does this need to be a dual output, or will it be multiple SADs?

- Do you know the environmental requirements?

- Do we know the max predicted environments to temp, shock, vibe, or any EMI, EMP, radiation?

- Are there any special qualification time requirements or time frame?

With this information when discussing options, we can help to chose a device that would have the largest “Qualification by Analysis” or “Qualification by Similarity” as possible to minimize the scope of the qualification effort.

FAQ's

-

Can the arming signals for a Safe and Arm Device, say for rocket motor ignition, be actual arm commands or do they have to be environmental events?

An arm event or inhibit can certainly be a discrete command from a user or a flight computer. However, environmental events are more unique and therefore fundamentally safer. A safety board for example wouldn’t want you to have Arm Event 1 and Arm Event 2 be the same discrete arming signal, they would want the two signals to be different and unique in some way. Ultimately, the safety board involved has the last say on which signals should be used for arming.

-

Can the electronic S & A send fire commands to high voltage as well as low voltage initiations and also detonate as well as deflagrate?

As far as low voltage and high voltage, if this system requires a high voltage safe and arm in the first place, the safety critical portion of that system must remain high voltage. But the systems do have the ability to fire low voltage initiators. An example of this would be a flight termination system which is initiating a bulk destruct charge.

-

For FTS applications that require arming before first motion, would terminate command prior to liftoff result in destructive output on the launch pad?

That’s typically not true on tactical systems, so a tactical missile that has a flight termination system (FTS) is normally going to launch and arm after first motion. However, some commercial launch vehicles or orbital launch payloads require arming on the pad to verify the arm state before launch and the requirements around whether you are capable of terminating on the pad fall on the particular range safety group you’re dealing with to determine that requirement. Sometimes the burden of that requirement will move to the flight termination receiver instead. So strictly, the answer would be, yes. If we’re armed on the pad and you send a terminate command, it will terminate. The flight termination receiver controls when that terminate command can be received. In other versions, we will include an inhibit, which allows the unit to arm on the ground and would not allow it to fire on the ground. However, when you include a feature like that it will undergo a lot of scrutiny from the Range Safety Group because that feature becomes a reliability question during flight. What if that feature never reactivated on launch night and you’re flying a dead FTS? If that burden of safety is on the safe and arm, there’s additional qual effort around ensuring that feature won’t malfunction. Or you can leave the safe and arm simple, where it will always terminate when it receives the terminate command and put that burden on the flight termination receiver.

-

Can the unit be commanded back to the safe state? And what if I abort?

This applies to the situation where you may be arming before first motion on a pad. The most common way is by allowing the unit to power down and safe itself. If armed, but launch is aborted, simply remove power. After the unit powers down, the internal bleed resistors will bleed the energy off the firing capacitor and will return it to a safe state. Then, upon power on it re-performs power on Reset and the Power On Self-Test. A return to safe has never been included on a warhead or FTS because, once you have the intent to launch and are flying, the ability to suddenly safe during flight is not desired. This feature would only be added to an FTS on an arm-on-the-pad configuration, which is another feature to be reviewed by the Range Safety Group.

-

For systems that are armed after first motion but prior to rocket motor engine ignition, do you recommend using ESAD outputs for inhibiting engine ignition or a separate device for the engine

inhibit?

In the case of a captive carry program which drops the vehicle off of the wing of an aircraft, the flight termination system is usually required to arm after separation but before ignition of the propulsive system. The ESAD’s are capable of providing an inhibit that prevents the activation of the propulsive system (usually a rocket motor). This output is typically a low voltage power source that drives a relay or switch. Most Range Safety Groups will allow the ESAD to control this type of inhibit. The ESAD output that is intended to initiate the flight termination destruct charges still needs to be a high voltage EFI, but outputs whose purpose is to inhibit the rocket motor ignition until after verification of an armed state need not be high voltage and can certainly be controlled by the ESAD.

-

Do we have keep alive capability? And if so, what are some typical durations?

We’ve implemented keep alive in several of our laser safe and arms. Our high voltage safe and arms have used keep alive in a variety of flight termination vehicles. The most common duration is a two second keep alive. Anything between 0 and 2 seconds typically has a significant margin on it. Most of our heritage products are at the two second mark. A keep alive feature can remove the requirement for the vehicle to have dedicated flight termination batteries

-

What are some of the typical vibration and shock environments these devices can meet?

Each device is qualified to the specification based on the environments of the vehicle that it was intended for. These safe and arms have been on aircraft captive carry environments, launch vehicle environments, tactical launch vehicle environments, and have been deployed in subsea and space.