Underwater Emergency Egress System

Product Description

The Underwater Emergency Egress System (UEES) is a severance assembly device to support pilots and crew needing to escape from inside a helicopter underwater. Our system is qualified and in the process of implementation into the Apache AH-64 Apache.

Key Features

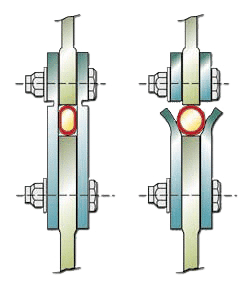

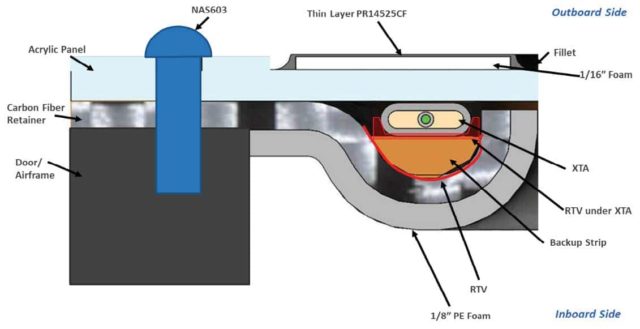

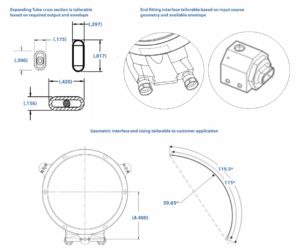

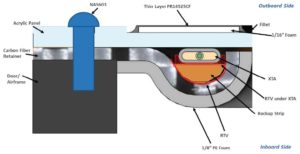

Using an Expanding Tube Assembly (XTA) to sever an acrylic target. XTA’s had and are being used in aircraft, missile and space applications to achieve severance or a shear along a plane. Examples of qualified platforms include the F-14, F-16 and Delta Rocket using a Mild Detonating Cord (MDC) sheathed within a flattened stainless steel tube, the device contains all combustion products to attenuate the overpressure due to explosive detonation while severing the 0.150” tri-laminate MIL-PRF-25690 acrylic. When initiated, the energy from the MDC ovalizes the flattened tube which breaks the acrylic.

The XTA is housed within a low weight carbon fiber retainer which holds the XTA in place during flight and functional activation. On the exterior of the acrylic, a thin layer of foam is coated with a sealant providing aid to the severance event and reducing the amount of flying acrylic debris. Covering the interior assembly is a thin layer of foam conforming to the retainer, resulting in overpressure reduction. The carbon fiber retainer remains intact reducing any debris in the cockpit.

Safer Underwater Emergency Egress

With this device we provide multiple improvements and enhancements over the current CFS which utilizes MDC held in place with a fiberglass retainer Safer aircrew egress in an underwater environment is enhanced by this design, which offers decreased Peak Pressure Acoustic Levels by a factor of 30 and reduced impulse levels. From the interior, the acrylic panel breaks off in one piece instead of multiple shards thereby reducing the risk of impact of sharp acrylic pieces that could injure the aircrew or damage their survival equipment. The acrylic break lip is straight and regular with a controlled perimeter. A non-abrasive layer allows intimate contact of the severance assembly to the acrylic without damaging the window.

The expanding tube fully contains all combustion products during function and is able to function within an explosive atmosphere (JP8) without igniting the flammable gas. Our robust design of the one piece retainer maintains integrity during open air and underwater functional events with no delaminating or breaking during function reducing the risk of pieces impacting and potentially injuring an aircrew member, and if present, any back-blast products. The exterior layer is protected from the environment and aids the acrylic severance. Finally, the entire assembly and external surface enhancements maintain the current optic limits.

Supportability

Expected shelf life is projected to exceed the current 96 months on the existing CFS. Expected DOT CA classification to be 1.4D UN0352. The UEES design is a drop in replacement for the existing CFS on the AH-64. It does require new SMDC Lines and flex lines due to the XTA’s manifold location. Also, time delay initiators are added for further reduce impacts from the pressure wave by staggering the firing sequence of the XTA’s design is adaptable for integration into other legacy or newly designed platforms. Successful qualification and acceptance of the test report was completed in 2015. Implementation into the AH-64 fleet began 2019.

Specifications

Functionality

The Underwater Emergency Egress systems XTA consists of the encapsulate Mild Detonating Cord (MDC) and an input manifold. A single high energy input tip is installed into the manifold. When activated by a crew member, the detonation wave transfers from the input tip and functions the unit through redundant booster shells. The booster shells propagate the detonation to the MDC which in turn propagate around the periphery of the crew station window.

The detonated MDC provides the stimulus to ovalize the stainless steel tube. The carbon fiber retainer holds the tube in place as the detonation event occurs. The shockwave travels through the acrylic, spalling and weakening the tri-laminate structure. Finally, the tube expands through the acrylic, completely severing the panel from the aircraft structure.