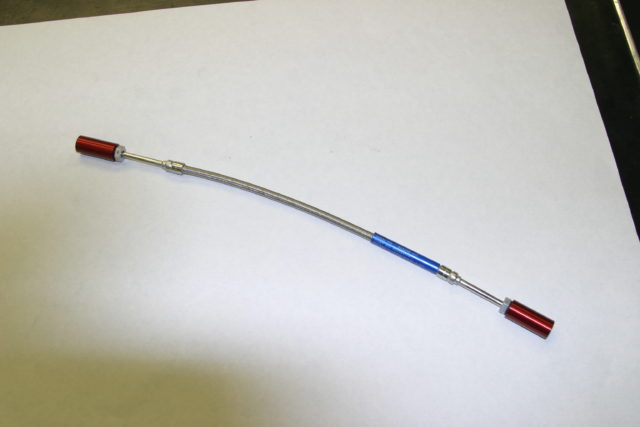

Flexible Confined Detonating Cord | Confined Detonating Cord

Product Description

Flexible Confined Detonating Cord assemblies provide point to point detonation transfer signal propagation across movable end points or provide installation flexibility when available free space makes it difficult to install rigid lines (SMDC). As with SMDC, the FCDC can be networked together with inert manifolds to propagate a detonation signal to multiple points / energetic devices that can perform work – operate/initiate energetic devices (PADs) but can accelerate cutting blades (cutters, guillotines or initiate cutting charges (MDC and FLSC).

Our FCDC designs are in aircraft escape, flight/thrust termination, event sequencing, deployment and severance systems. Additionally, our experience with the interface designs provides our customers with the proper gaps, standoffs, port dimensions of manifolds and other attaching devices.

When safety and accuracy are mission critical, our Flexible Confined Detonating Cord Assembly (FCDCA) provides a robust, high-strength, flexible answer for the demanding environments in tactical, strategic and space missions.

Key Features

How Flexible Confined Detonating Cord Works

Flexible Confined Detonating Cord Assemblies are ordnance transfer lines which propagate a detonating explosive stimulus between movable installation points in aircraft, spacecraft or tactical missile sequencing systems. This detonation velocity runs between 6,000-8,000 meters per second depending on the explosive used in the Mild Detonating Cord (MDC) train, i.e. HNS most prevalent).

Typical construction of the FCDC consists of flexible braided multi-layer sheaths of fiberglass (or Kevlar) containing, at the center, 2.5 grains/ft MDC with aluminum, silver, tin or lead as the sheath material. The end termination for each FCDC are very similar to Shielded Mild Detonating Cord (SMDC) which include internal pressed transition charges in the ferrule and welded pressed booster shells to the end termination with threaded fittings for installation at the mating ports.

Specifications

- Core Load

2.5 grains/foot Hexanitrostilbene, WS5003F, Type II, Grade A; end fittings Type I, Grade A HNS - Detonation Velocity

6500 +/- 500 meters/second - Strength

End fittings: 350 lbs minimum applied at a rate .5 to 4 lbs minimum - Dent Output

.04 inch (min) in aluminum dent test blocks over the temperature range -65oF to +200oF per MIL-STD-331 - Containment

Upon functioning, No ruptures – out-gassing allowed. - Flexibility (Mechanical Endurance)

20,000 flexure cycles around a bend angle of 180o over the temperature range of -65oF to +200o F at a rate of 6 cycles per minute Laboratory Tests - Operating Temperature

-65°F to +200°F - Shock

20g, 11ms - Vibration (Sine)

2-5g, 9 hours - Salt Fog

48 hours - Sand and Dust

28 hours @ +145°F - Impact

10 lbs – 16 ft. drop - Tensile Strength

650 lbs. ultimate