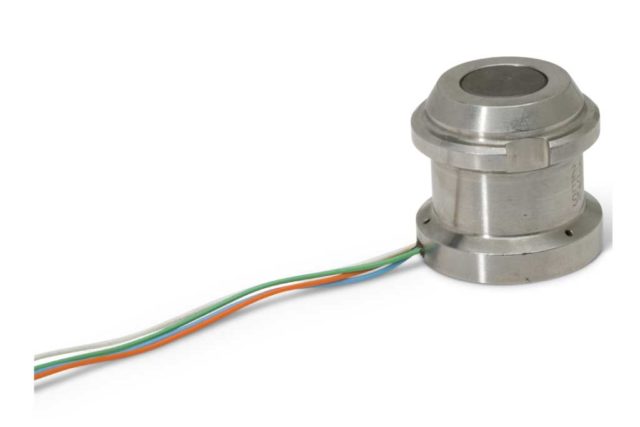

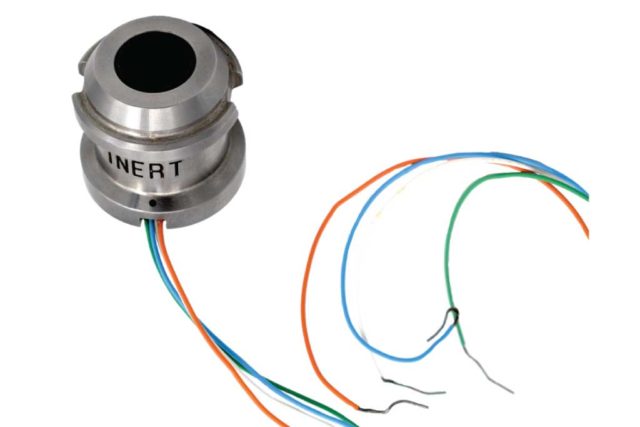

Pyrotechnic Pin Puller

Product Description

Consider the pin puller is a ballistic thruster in reverse, it is used to activate latch releases, release locking pins or move mechanisms to perform work and in a variety of applications. Our compact, pyrotechnic pin puller delivers precision movement on command, securing or releasing a variety of payloads. We will customize to meet any mission-critical need, including the controlled release of:

- structural fittings

- mechanisms

- rods

- cables

- booms

- parachutes

Key Features

Functions

A pin puller is almost unlimited for one shot type devices. They are used for emergency door release on helicopters and space capsules, fin and wing release, fuze arming, satellite release systems and missile release.

- Single and dual initiation

- Feedback signal design

- Corrosion resistant elements

- Wide operation temperature range

- Space rated

How A Pyrotechnic Pin Puller Works

An ordnance actuated or pyrotechnic pin puller is typically used to restrain a mechanism under low to extreme side loads and then rapidly releases them for a clean separation. The pin pullers retain all explosive hot gases with the use of various elastomeric seals. Pin pullers can be actuated by an electrical explosive device (pressure cartridge), a mechanical primer initiated device (gas generator), a linear detonation transfer line (SMDC, FCDC, ETL, RDC) or a laser actuated ordnance device (laser initiated squib or detonator). Function time in most applications is under 20 milliseconds from application of input energy.

The pin puller withdraws rather than projects a mechanical element. Applications include unlocking, releasing of spring-loaded devices and the pulling of pins from heat shields on meteorological probes. An explosively actuated pin puller can be utilized any time the withdrawal of a mechanical structure is required.

The energy from any of these devices expands rapidly in a confined space, resulting in a volume change which drives the pin inside of the pin puller body. Retraction length of the pin is controlled by the envelope of the body. The pins retract rapidly in most applications, creating a mechanical shock when the piston reaches full stroke. Dampeners can be installed into the pin pullers when lower mechanical shock is needed. In many applications, the shock of other devices being released is as great as, or greater than, that generated by pin puller actuation.

A pin puller can be sized for a wide variety of geometries and they can in some cases include switches to verify pin retraction has occurred.

Specifications

Electrical Characteristics

- Bridgewire Resistance

1:0 ± .1 ohms - Insulation Resistance

>50 megohms at 500 VDC - Dielectic Strength

.1 ma at 500 VRMS - Electrostatic Discharge

25 KVDC per MIL-I-23659 - No-Fire

1 amp/1 watt for 5 minutes - All-Fire

3.5 amps with a 50 millisecond pulse

Other Characteristics

- Temperature Range

-51°F to +160°F - Temperature Shock

20 cycles between extremes - Shock

1400g @ 10,000Hz (and per vehicle environments) - Shock

Up to 75 g’s in varying axes - Random Vibration

Performed as hot and cold - Function

Piston retracts .41 inch with 100 pound side load (for Javelin type) - Function Time:

≤10 ms - Hermetic Seal

≤1 x 10-6 cc/sec Helium

Specification Questions

Questions to Consider

- Application – what are you trying to accomplish?

- What are your tensile/shear and side loads?

- What are your space constraints?

- Is containment required?

- Redundancy requirements?

- Input power requirements – electrical, ETL, mechanical?

- Environmental requirements?

- Qualification requirements?

- Military or other requirements?

FAQ's

-

What is the pull force (axial/radial) and size?

Our pin pullers are designed to meet your needs.

-

What is the total length the pin puller extends?

This product extends to multiple lengths. We make it custom for your needs.