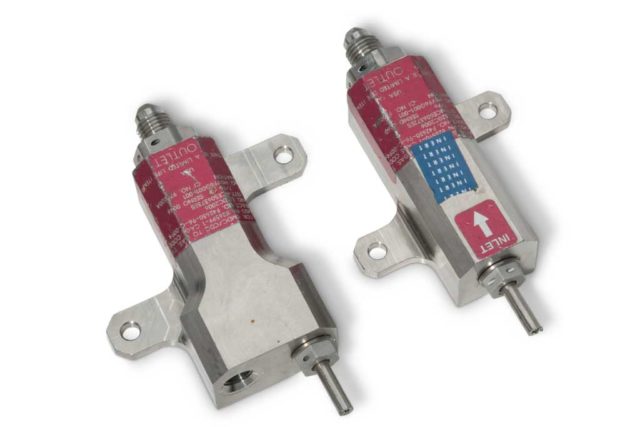

Hot Gas Initiator

Product Description

A Hot Gas Initiator provides a method of converting one signal transmission method into another. Typical conversion types as part of an Emergency Escape System include:

- Hot gas (i.e. from an Ejection Seat System) to a detonating signal (i.e.: to an attached Shielded Mild Detonating Cord (SMDC), Flexible Confined Detonating Cord (FCDC), Confined Detonating Cord (DCD) or Rapid Deflagrating Cord Transfer Line(RDCTL)

- Detonating signal to hot gas

- Hot gas to a deflagrating signal (i.e. HGI to attached RDCTL)

Key Features

- Used to transition from ballistic hot gas to a detonation or deflagration or vise versa

- Explosive loaded & inert versions

- Normally used as interface between ejection seats and the cockpit pyrotechnic system

- Primary use is aircraft emergency escape system

How Hot Gas Initiators Work

GAS TO ETL (HIGH ENERGY HE OUPUT – DETONATIONS)

This initiator receives Ballistic Hot Gas from an ejection seat applying it at the inlet end of the housing. A shear pin securing the piston type-firing pin is severed, releasing the firing pin and impacts a percussion primer. The output of the percussion primers is funneled to a transfer charge containing a load of primary and secondary explosives. The percussion primer output ignites the primary explosive material. The high energy output of the primary initiates secondary explosive material providing a detonating output. The output of this transfer charge initiates the attached ETL allowing it to transfer either a detonating or deflagrating signal along its length.

ETL (HIGH ENERGY ETL – DETONATION) TO GAS

This initiator receives a detonation signal from an ETL HE end tip. The HE output drives an annular firing pin into two percussion primers. The output from the primers initiates an ignition charge. This charge in turn ignites a propellant gas generating explosive material. The gas pressure is routed through a braided hose to the ejection seat gas system so the remaining ejection events can occur.

GAS TO RDCTL (PERCUSSION PRIMER)

We have designed and manufactured 100’s of different cutters for 100’s of applications. Qualified and used in various military, commercial, and aerospace platforms including spacecraft, launch vehicles, aircraft (military and commercial), satellites and multiple missile platforms.

Advantages

The advantage of a hot gas initiator is the ability to mix different signal types in one system without severe design or reliability penalties. The HGI function either at the beginning of the canopy removal sequence or after the canopy system has functioned and the seat is ready to ejection. In the case of SMDC to Gas this is usually the later situation as the canopy removal is associated with a jettison system rather than CFS / TRS. HGIs are manufactured to contain all the by-products of combustion regardless of type. Design can be both inert and explosive loaded. They can be designed with single or dual input.

Specifications

- Operating Temperature

–65°F to +200°F - Leak Rate

1×10-5 cc / sec. Air at 1.0 + 1 Atmosphere - Vibration

5-2,000 Hz sinusoidal vibrations at 10 g’s maximum amplitude per MIL-STD-810, Method 514.1, Procedure I - Shock

10 shocks of 15 g’s maximum acceleration in 8 milliseconds maximum, exceeding 8 g’s for 11 milliseconds maximum, per MIL-D-23615 - Drop 6 feet onto a steel plate at least 2 inches thick, over concrete per MIL-D-21625; 40 feet onto a steel plate over reinforced concrete per MIL-D-21625

- Temperature/Humidity Cycling in two and three week segments from –80oF to +160oF at 90% RH per MIL-D-21625

- High Temperature

+200°F +/- 5°F for 1 hour per MIL-D-21625 - Low Temperature

-65°F +/- 5°F for 1 hour per MIL-D-21625 - Sand/Dust

.3 +/- .2 gm./ft. 3 dust concentration, with a maximum air velocity of 1,750 +/- 250 fpm and +145°F maximum per MIL-STD-810, Method 510 - Salt Fog

48 hours at +95°F +/- 2.5°F per MIL-STD-810,Method 509 - Icing

-65°F to +100°F +/- 5°F at 90% RH, then returned to -65°F and functioned, per MIL-D-23615 - Platform Use & Heritage

F-15, F/A-18, B-1B, Scorpion, Improved CFS w/Inerts