Satellite Payload Release & Sequencing

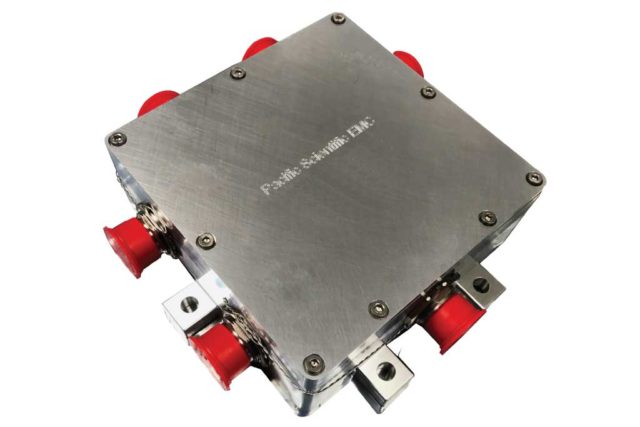

Product Description

Our payload release and satellite sequencing system deploys hundreds of vehicles with microsecond repeat-ability and sub-millisecond sequencing. And… with our high reliability and our precision timing… be assured of no satellite tip offs. Our satellite separation system ensures the satellites remain in place securely from launch until the precise time they are meant to be released into orbit. With over 1000 satellite payload release separations occurring with 100% success rate. The modular components of our system enable compatibility with almost any dispenser, launcher and satellite on the market.

On March 21, 2020 PacSci EMC proudly participated in the successful deployment of 34 satellites into Low Earth Orbit (LEO). The release of these satellites from the launch vehicle dispenser structure is a precision operation choreographed by our Payload Release Sequencing System (PRSS). To date the PacSci EMS PRSS has successfully sequenced 4,000 on orbit events to successfully deploy 500 satellites.

What may be less well known is how PacSci EMC came to develop the PRSS technology. With the growing use of airbags in the 1980s and 1990s, the automotive industry established a consortium of companies to develop communication & sequencing protocol. A safe-by-wire technology was developed to initiate the growing number of airbags found in modern vehicles. Ultimately the technology was deemed too expensive for the high volume production of the automotive industry. PacSci EMC recognized the potential application for the technology in the aerospace industry and acquired the intellectual property in 2001. For use in aerospace application, we branded the technology as Smart Energetic Architecture (SEA).

Since 2001, PacSci EMC has successfully implemented SEA technology in numerous applications. For the deployment of large satellite constellations, Smart Energetic Architecture offers many advantages

Differentiation

- Flight qualified on 74 One-Web Satellite Separation

- Flight qualified on space SRM Attitude Control/Delta V ignition system for Cubesats

- Designed for space (vehicle radiation, thermal, vacuum, shock, vibration etc)

- Highly flexible mission configurations. Mission sequencing can be hardcoded or user configurable

What our Satellite Payload Release system can do

- Command, deploy, initiate or release an unlimited number of satellites

- Each device can be status’d and deployed separately

- Program pre-scripted or on the fly sequences

- Release any combination of devices simultaneously

- <1ms timing and simultaneity

- Highly reliable & safe

- Space flight proven

- Configured for redundancy

Key Features

- Highly Configurable

– Permits release of devices in any sequence – single, multiple simultaneous or sequential - Low power

- Devices are wired in parallel

- No current surges during firing

- Firing circuit conductors are very short and low inductance

- Low component count

- Hermetic design

- Firing energy not present during built-in-test

What these key features offer:

- Multi-satellite release solution—integrated mechanical & electrical system and harnessing

- Parallel bus allows for minimized system harness mass

- Configurable mounting options—enables flexibility, smaller footprint, less weight/wiring

- High reliability and precise timing—no satellite tip off

- Flexible & scalable architecture

- Command many individual separation events (e.g., 16, 72, etc.). Demonstrated up to 384 events on one vehicle

- Real time status/arming/firing feedback, bi-directional network bus architecture over a variety of serial communication options (Ex: RS422)

- Commands a mix of pyro devices, motorized lightbands and non-explosive actuators

- Very low power—ability to sleep/no power draw. Has demonstrated mission durations from hours to months

Benefits

- Improved margins on system’s electrical power budget

- Significantly reduces cable weight

- Reduced EMI emissions and power requirements

- Reduced radiated EMI

- No ground loop current during firing

- Built-in-test with feedback

- Easily integrates into existing flight computers

- Different types of release systems freely intermixed

- Meets environment requirements

- Easy mission expansion

Applications

Reliable Satellite Sequencing System

Which ever payload dispenser system being utilized trusting your dispenser with a release system that has never flown could be a costly endeavor. The good news is our satellite separation and deployment system has launched. Our system is successfully used today on spacecraft payload dispensing systems for satellite separation and release. We have deployed multiple small satellites in space, particularly LEO, with distribution occurring on-orbit into their respective mission orbits.

Our payload and release system mounting options – enable flexibility, a smaller footprint, less wiring and in the end, less weight. Release in your precise orbital slots for perfect mission control AND… release on command, when commanded, with no possibility of an inadvertent launch.

Challenges and Solutions in Satellite Payload Release

The environment once you leave earth’s atmosphere is extremely harsh. Counting on devices to work outside this atmosphere requires years of experience. We have that experience and expertise. Operational in any environment, our system is also adaptable to non-explosive or pyrotechnic devices providing reliable functioning, on command, when commanded and all programmed to mission specific requirements.

Critical to mission success, our proven and reliable satellite separation and release system allows for a wide range of release device options. Including:

- non-explosive

- pyrotechnic

- smart connectors

- smart initiators

- cutters

- separation nuts

- space standard initiators

- detonators

We configure and tailor the system to the device working best for its mission. Functioning, on time and only when it’s time, with a clean and precise satellite separation and release.

If you would like to see our system in action, please watch this OneWeb satellite launch, at 51 seconds you will see the upper stage release the in space on command, when commanded. That’s reliability in action.

Satellite Launch

With three types of earth orbits, satellites launch most commonly into Low Earth Orbit or LEO. The height of the orbit, or distance between the satellite and Earth’s surface, determines how quickly the satellite moves around the Earth. An Earth-orbiting satellite’s motion is mostly controlled by Earth’s gravity. As satellites get closer to Earth, the pull of gravity gets stronger, and the satellite moves more quickly. The amount of energy required to launch a satellite into orbit depends on the location of the launch site and how high and how inclined the orbit is.

Satellites in high Earth orbit require the most energy to reach their destination. Satellites in a highly inclined orbit, such as a polar orbit, take more energy than a satellite that circles the Earth over the equator. A satellite with a low inclination can use the Earth’s rotation to help boost it into orbit. For a more detailed description visit our friends at the European Space Agency. And, for an interesting example of two satellites in one orbit, read this NOAA article regarding polar orbits.

Why does this matter?

With a configured Satellite Payload and Release system like ours, depending upon the launch vehicle and the dispensing system, we are able to provide precise on-orbit placement of the satellites, exactly where and when. With so many options, we can get you where you want, when you want.