Flexible Detonating Cord (FDC)

Product Description

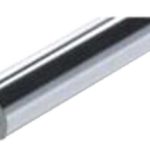

Flexible Detonating Cord (FDC) is a type explosive transfer line consisting of metal-sheathed energetic material drawn in a round configuration with booster shell end tips.

Typical FDC is manufactured using Mild Detonating Cord (MDC) with minimal outer covering. An outer sheathing of flame retardant semi-rigid tubing produces a durable and flexible energy transfer line that permits easy routing in confined spaces. Its inherent reliability can be enhanced in system applications through the use of crossovers of the same energy transfer lines. High energy output tips are available with various explosive loads tailored to application requirements. End tip configurations can be provided to replicate Shielded Mild Detonating Cord (SMDC) Assemblies.

Key Features

- Malleable, flexible, and jagged

- Full confinement explosive by-products

- Long service life

- Unresponsive to false ignition

- Qualified to RCC 319 and other heritage Range Safety standards

- Applied to numerous national and global ranges

- High dynamic and thermal environmental capability

- Tight bend radii

How Flexible Detonating Cord Works

Our FDC’s provide point to point detonation signal transfer allowing for the networking of explosive / pyrotechnic components. The loaded booster end tips are used for reliable detonation input and output. The detonation output can transfer to other FDC’s, to drive mechanical components (pin pullers, cable cutters, etc.) or to initiate larger explosive charges. FDC’s are best suited to application where containment of combustion by-products is not required and flexibility in routing during installation is desired. FDC is primarily used in missile, munitions and target vehicle Flight Termination System (FTS) applications, where byproducts of combustion containment is not required

Applications

Our FDC’s are range safety approved for programs such as Standard Missile, Rocket Systems Launch Platform (RSLP), Payload Launch Vehicle (PLV), Supersonic Sea Skimming Target (SSST) and Minotaur IV.

Specifications

- Weight

4.60g per end tip (.375-24 UNF) plus 0.70g per inch of length - Pull Test

100 lbs. - Temperature Cycling

-65°F/+368°F 8 Cycle/ 2 Hours Minimum - Operating Temperature

–65°F to +165°F - Initiation

No. 6 Blasting Cap or various qualified devices available through PacSci EMC (Arm Fire Initiators, Lanyard Pull Initiators, Electrical Detonators, EFIs, Safe Arm Devices) - Output

0.010 inch minimum dent depth in steel plate

0.040 inch minimum dent depth in aluminum plate - Sinusoidal Vibration

45 – 80 Hz, 21G

170 – 200 Hz, 12G

300 – 400 Hz, 12G

450 – 550 Hz, 86G

600 – 700 Hz, 74G

720 – 900 Hz, 84G

700 – 1000Hz, 70G

1600 – 1750 Hz, 22G - Shock

100 – 10,000 Hz, 105 – 7350G - Acceleration

20G’s, 5 Minimum

3 Axis, Both Directions - Random Vibration

65.9 GRMS - High Temperature Storage

+160°F, 40 – 60RH, 30 Days

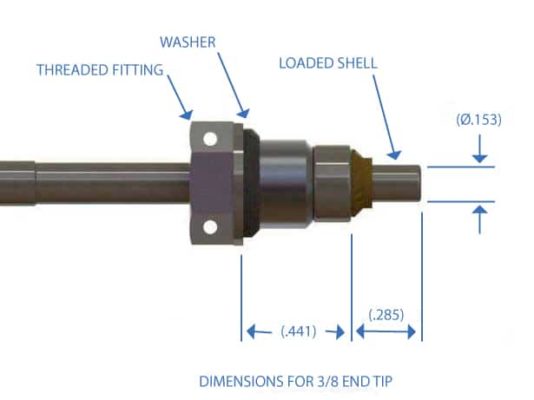

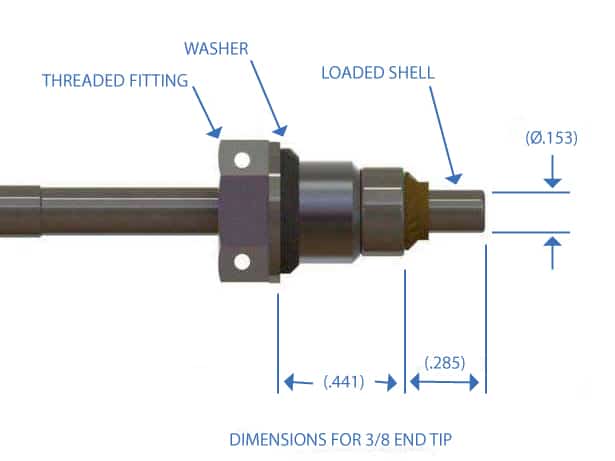

Interface

Typical 3/8 Threaded End Fitting Configuration

FAQ's

-

What are detonating cords used for?

Our FDC’s provide point to point detonation signal transfer allowing for the networking of explosive / pyrotechnic components.

-

How does detonator cord work?

The loaded booster end tips are used for reliable detonation input and output. The detonation output can transfer to other FDC’s, to drive mechanical components (pin pullers, cable cutters, etc.) or to initiate larger explosive charges.

-

What is the outside diameter of your FCDCAs?

Approximately 0.250-inch

-

Do you have different end fitting sizes that can be chosen?

Yes. Common sizes are 3/8", 7/16", 1/2" and 5/8".

-

Do you FCDCA's vent when fired?

They can at certain low temperatures or at any temperature with a severe bend.

-

What is the longest and shortest FCDCAs you can manufacture?

6-inches - 10 feet