Rapid Deflagration Cord Transfer Line

Product Description

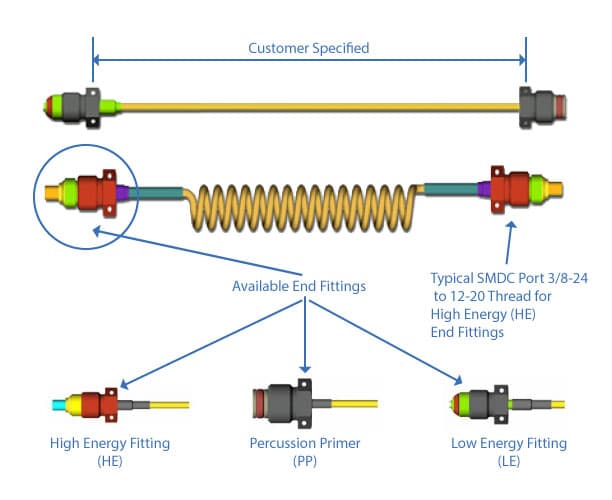

The Rapid Deflagration Cord Transfer Line (RDCTL) offers a robust design with flexibility required in modern emergency escape systems. That flexibility includes smaller diameter for easier routing, an assortment of end tips for various input and output combinations (LE- Low Energy, HE- High Energy, PP- Percussion Primer), high tolerance to extreme environmental conditions and durable materials to meet the physical demands of emergency egress systems. RDCTLs use the basic Rapid Detonation Cord (RDC) confined in an outer casing compromised of braids and extrusions or a metal tube with end fittings for a sealed system.

RDC’s are designed in a number of different configurations. The outer construction can be enhanced using braided fiberglass, Kevlar and polyurethane for maximum confinement in a flex application to an aluminum or stainless steel tube for form-able, but semi-fixed, routing conditions.

Key Features

Rapid Deflagration Cord Transfer Line Function

RDCTLs do not vent by-products of combustion or breach the outer tubing when fired as some other transfer lines. This feature is extremely important when considered in an explosive atmosphere environment or exposure to air and ground crew personnel. Their flexibility and small size allow for easy routing in the complex structure of modern aircraft. RDCTL configurations can reduce the total explosive weight used in a system (at least 45%) by the use of the percussion primer end fitting and making typical arm fire initiators, inter- connects, actuation initiators, one ways and mode selectors inert. By making these components inert, it reduces their long-term support costs by eliminating the need to replace explosive loaded components. RDCTLs are lighter than typical transfer lines such as SMDC and FCDC.

Specifications

- Operating Temperature

–320°F to +700°F (Refers to operating temperature of the RDC material only) - High Temperature Storage

All lines at+350°F for 50 hours except lines with PP end tip then +200°F for 50 hours (Limiting factor is the percussion primer) - Hermetic Seal

£ 1×10-5 cc/sec. Air - Gunfire Vibration

100 – 1,700 lbs. force typical - Salt/Fog

MIL-STD-810, Method 509.2: 5%+1% Salt Solution at +95°F ± 5°F for a period of 168 hours - Temperature, Shock, Humidity & Altitude (TSH&A)

MIL-C-83124 at 70K Feet Altitude. 3 durations: 28 days, 56 days, and 84 days. Temperature range from –65°F to +160°F and humidity between 50% and 95% RH per test method requirements - Flexibility Test

MIL-C-83124 paragraph 4.5.11.10: Temperature –80°F & stabilized, then placed in+100°F/90% relative humidity until ice disappears, then –80°F & stabilized, then fired at –80°F - Pressure Cycling

Units subjected to 100 pressure cycles, 50 at –65°F and 50 at +250°F with pressure between .83 inches Hg to 29.92 inches Hg - Vibration

Sinusoidal Cycling (5-50 Hz) for 30 minutes along 3 axes for each temperature of –65°F, +70°F, and +200°F with one cycle completed over the range in approximately 7.5 minutes, Random Vibration (50-2000 Hz) for 60 minutes along each axes for each temperature

Interface

Our rapid deflagrating cord transfer line can be customized to fit many customer envelopes.

We offer several configurations of Percussion Primer and Low Energy end fitting configurations (threaded fitting similar to SMDC and insert / clip style to fit a Rapid Deflagrating Cord Transfer Line). For High Energy end fittings, the interface dimensions are the same as SMDC 3/8, 7/16 and ½ configurations – please refer to the SMDC web page.