How To Increase Missile Range Accuracy

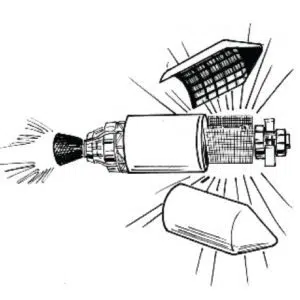

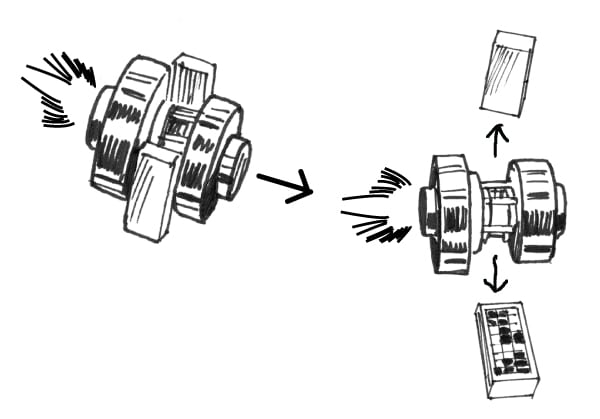

The range and accuracy of a projectile are determined by factors such as projectile design, launch mechanism, and environmental conditions, with considerations like aerodynamic efficiency, weight, balance, barrel length, rifling, propelling charge, atmospheric conditions, and earth’s spin, while incorporating features like high ISP propellant and projectile guidance systems can maximize both range and accuracy in weapons systems.