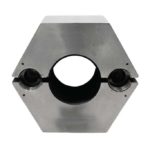

Separation Nut

Product Description

The separation nut is a pyrotechnic device designed to perform two functions – keep a pre-loaded assembly of two sets intact and then, upon an electrical signal, releasing the assembly. Known as a Hold Down and Release Mechanism (HDRM), they are a high strength, fastening hardware with the ability to separate and/or release components or structures on demand. As a pyrotechnical solution for critical release events, the most common uses include satellite deployment along with clamp release applications for weapons launch systems. Many of our sep nuts are used for in orbit deployment of antenna reflectors and solar generators as HDRMs

Whether in space, on aircraft or in the sea, dependability is required for mission critical systems needing hold down and release mechanisms that are designed and developed for low shock. Our highly reliable separation nuts are used for applications in submarine, launch vehicle, satellite, and payload systems. An example would be as an HDRM for CubeSat and SmallSat launches. Our separation devices are custom made to meet your mission requirements, from the nut size to the specific materials, the success of your application is at the center point of our design.

DOWNLOAD DATASHEETS

Key Features

Functions

These restraint and release devices may also provide the release or separation of structures such as multi stage launch vehicles, nose cones and capsules, underwater systems, launching pads, booster rockets, tanks, and other gettisonable equipment.

- Pyro and Non-pyro initiation

- Redundant initiators

- Fast actuation time

- Space-rated materials

- Extended operating temperature range

- Qualified for human-rated programs

- Debris-free application

- Various initiated configurations available

- Low induced shock

How Separation Nuts Work

Designed to provide mechanical release of various component devices, the most common design configuration consists of a housing containing a segmented thread interface which is compatible with the threads on the mating stud.

Most separation nuts are externally actuated using a cold gas system or pressure cartridge. When the release nut is pyrotechnically actuated the threaded segments will be allowed to move away and expand, resulting in the release of the mating device.

Specifications

- All-Fire

5.0/20 millisecond pulse - No-Fire

1 amp/1 watt for 5 minutes - Operating Temperature

-65 °F to +225 °F - Axial Load Retention

Designed to meet application output force - Applicable Specifications

Qualified to:

MIL-N-82943A

MIL-DTL-23659

Interface

They can be customized to fit many customer envelopes.

FAQ's

-

What is a Sep nut? What is a separation nut?

The separation nut (Sep nut) is a pyrotechnic device designed as a high strength, fastening hardware with the ability to separate and/or release components or structures on demand.

-

How does a Sep nut work?

Designed to provide mechanical release of various component devices, the most common design configuration consists of a housing containing a segmented thread interface which is compatible with the threads on the mating stud. Most separation nuts are externally actuated using an impulse or pressure type cartridge. When the release nut is pyrotechnically actuated the threaded segments will be allowed to move away and expand, resulting in the release of the mating device.

-

Is it dual or single initiated?

We provide both dual and single initiated

-

How do I size the sep nut?

Give us your tensile strength requirement and we will provide a size