Mode Selector

Product Description

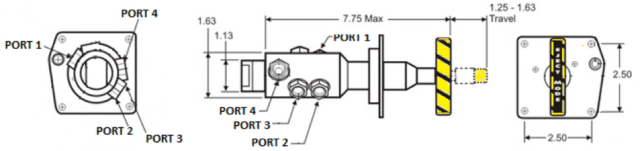

Pilot safety is paramount and when a crew needs to eject, they must know their systems will work on time, every time. Our 3-Mode Selector, a cartridge actuated device also known as an Explosive Sequence Control (ESC), PacSci EMC P/N 820833-4 & 826213-1, is a manually operated pyrotechnic device that transfers the stimulus of high energy output ETL (i.e. SMDC, FCDC, RDCTL, etc.) from one ejection sequence to another. For military aircraft, selector of choice is 820833-04 on the F/A-18, T-45 and TAV-8B while the 826213-1 is used on the two seat F-15. Both have the same construction other than the F-15 unit has different positioning of the ports in relation to the other. Its function as a part of the aircraft crew emergency escape system is to provide a selection of ejection modes by transferring the single input energy stimulus to any one of three output ports. The unit’s construction contains all fragments produced during its functioning.

Key Features

Mode Selector Functions

- NORMAL: With the handle in this mode and initiation occurs in the front cockpit, both ejection seats will eject. If initiated from the rear cockpit, only the rear seat will ejection.

- SOLO: This mode is used when the rear cockpit is not occupied. When the front cockpit pilot initiates ejection only the front seat will ejection, reducing the time waiting for the aft sequencing to occur.

- REAR: With the handle in this position both the front and aft ejection seats will eject, regardless of who initiates ejection and the aft seat will always go first.

Leaving Safety to Chance is Not an Option

Our improved version is qualified to the requirements of MIL-D-23615 while the explosive transfer shaft is separately qualified as a sealed, replaceable cartridge to MIL-D-21625.

When Lives are at Stake, The Mission is Clear

The design of our explosive sequence control features a replaceable explosive transfer shaft, the only component requiring replacement at service life change out. The ports are different sizes to prevent the wrong ETL being installed into the wrong port, thereby ensuring proper installation and a safe ejection. Approximate weight of the unit is 1.25 lbs.

Specifications

- Operating Temperature

–65°F to +200°F - Leak Rate

1×10-5 cc/sec. Air at 1.1 + 1Atmosphere (Explosive shaft only) - Handle Cycling

15,000 cycles minimum - Ultimate Load

150 lbs. - Actuation “Force & Stroke

NORMAL to AFT INITIATES (90°) with 20-30 lbs. pull in 1.25-1.63 inches - Low Temperature

Conditioned at -65°F for 16 hours, then fired successfully. - High Temperature

Conditioned at +200°F for 22 hours, functioned successfully - Altitude

1 hour at equivalent 80,000 at -65°F - Salt/Fog

ASTM B117 for 168 hours - Dust

MIL-STD-810 Method 510, at +200°F for 28 hours. - Ice Condition

16 hours at -65°F - Vibration (non-gunfire)

5-2,000 Hz – 5 g’s to 10 g’s, 9 hours/axis - Vibration (gunfire)

5-500 Hz – 5 g’s to 10 g’s, 2 hours/axis, Mil-STD-810, Curve Z - 6 & 40 Foot Drop

Dropped Firing Mechanism Up, Down and Side, fired successfully. - Shock

30 G with nominal duration of 11 milliseconds for a total of 18 impacts. - Temperature/Humidity

28 days at -65°F to +160°F @ 90% Relative Humidity - Altitude

With ports open, 100 pressure cycles at +200F with absolute pressures between 29.92 inches Hg and 1.32 inches Hg. No adverse effect to initiators. - Fungus

MIL-STD-810 Method 508.1, Procedure I. No Fungus Growth. - Platform Use & Heritage

F-15, F/A-18, T-45, AV-8B