Electronic Ignition Safety Device

Product Description

The eISD is used for mission critical applications where a reliable initiation device that can be networked from a central ESAD can be utilized for multi-point initiation. This architecture saves the customer weight and cost by utilizing one set of common sensors to share among multiple ignition safety devices. Traditionally, each eISD would have its own accelerometer and other environmental sensors. In addition to ignition systems this technology is directly applicable to fuzing applications. The safety requirements for multi-point fuzing is the same as for ignition. The differences are the utilization of a detonating EFI rather than a deflagrating EFI in each remote ESAD.

Key Features

- High voltage (>500V) and static and dynamic inhibits used for ordnance system safety

- Newest technology

- Small and lightweight

How Ignition Safety Devices Work

The electronic Ignition Safety Device (eISD) contains an integral Exploding Foil Initiator (EFI) co-located in the same mechanical package, and therefore is close coupled (extremely low inductance and resistance) for extremely high reliability functioning. The eISD is part of a distributed Electronic Safe and Arm Device (ESAD) with one Central ESAD and multiple Remote eISDs. The remote eISDs are Arm/Fire devices that receive a high voltage low current input from the central ESAD and charge up the high voltage circuitry to a desired voltage, then when commanded, eisd discharges this energy into an EFI. We have an EFI design that includes an internal Thru Bulkhead Initiator (TBI) capable of withstanding rocket motor back-pressure after functioning.

The eISD includes High Side Static P-Channel Switch, Low Side Static N-Channel Switch and an N-Channel Dynamic switch to comply with MIL-STD-1901A. These inhibits are unique to meet the safety board requirements. The dynamic inhibit is controlled by the proper sequence of the other two inhibits. A communication bus is utilized to select the appropriate remote ISD to function. Each networked bus allows for up to 48 multiple point remote eISDs to be connected. Each eISD is independently Armed and Fired with very precise timing of events. The unique inhibits can be controlled from Acceleration, Break-wires, switches etc. Our designs can be completely interchangeable with most standard legacy ISD designs.

Applications

We have qualified and are producing a dual output eISD for various missile platforms for over 15 years. This heritage was utilized to develop this new multi-point eISD (both Series 255, Series 265 and Series 100), with much of the same qualified components and processes from the production programs.

Specifications

eISD Specifications

- Available Inputs

Dynamic Inhibit:

The proper sequence of ENABLE and ARM will remove the dynamic inhibit

Ordnance Power:

28VDC

Arm:

10vac signal created from a safety switch

Enable:

30Bit encoded digital signal created from a proper Acceleration Profile

Fire:

SEA network bus, serial bus with 4 analog levels and encoded signals for device selection, status and FIRE - Output

Time to first pressure: < 4milliseconds

Output pressure: 600 to 1500 psia (10cm3 test bomb)

The output can be tailored to meet specific application needs - No-Fire

≥ 500 Volts, 0.001 probability to fire at 95% SS lower confidence - Backpressure

Capable of withstanding up to 10kpsi backpressure - Packaged Weight

37-50 grams - Operating Temperature

-54°C to +71°C - Applicable Specifications

Qualified to MIL-DTL-23659

MIL-STD-1901A for motor ignition

MIL-STD-1316 for fuzing applications

EFI qualified to MIL-DTL-23659D

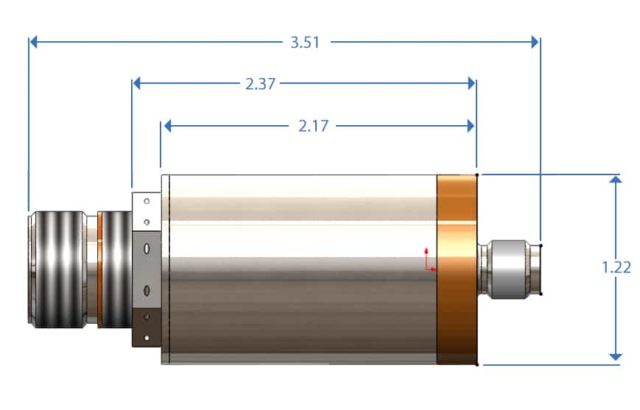

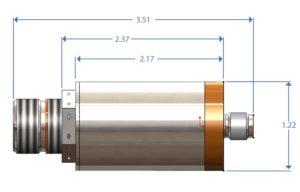

Series 100 Specifications

- Available Inputs

Dynamic Inhibit:

The proper sequence of ENABLE and ARM will remove the dynamic inhibit

Ordnance Power:

28VDC

ARM:

Input Signal of varying voltage interfaces available

Enable:

Input Signal of varying voltage interfaces available

FIRE:

Input Signal of varying voltage interfaces available - Output

Time to first pressure: < 4milliseconds

Output pressure: 600 to 1500 psia (10cm3 test bomb)

The output can be tailored to meet specific application needs - No-Fire

≥ 500 Volts, 0.001 probability to fire at 95% SS lower confidence - Backpressure

Capable of withstanding up to 10kpsi backpressure - Packaged Weight

37-50 grams - Operating Temperature

-54°C to +71°C - Applicable Specifications

MIL-STD-1901A for Motor Ignition

Mil- Std-1316 for fuzing applications

EFI qualified to MIL-DTL-23659D

FAQ's

-

What Rocket Motors have your iSD's ignited?

Several Rocket motors, solid a liquid fueled