ALEX MCGILL | DIRECTOR OF BUSINESS DEVELOPMENT, AIRCRAFT AND UNMANNED SYSTEMS AT PACSCI EMC

Regulations & Safety

At PacSci EMC, we must follow multiple regulatory requirements for explosives to protect people, facilities, and our environment. These requirements include but are not limited to:

- Bureau of Alcohol, Tobacco, Firearms & Explosives (BATFE); Title 27, Chapter II Code of Federal Regulations (CFR)

- CFR4145.26 DOD Contractor’s Safety Manual For Ammunition and Explosives

- Occupational Safety & Health Association

- Pipeline & Hazardous Materials Safety Administration (PHMSA)

- Transportation Requirements – US Department of Transportation (DOT), 49 CFR

- Export (ITAR or commercial), US Department of State (DOS) or Commerce (DOC) licensing coverage, as required

This article will not go into depth about these requirements but do know they exist and help guide our products and how we interact with different customers in providing solutions.

It is extremely important for the manufacturers of these devices and their end users to receive specific training guidelines for individuals and operations.

These guidelines keep people and infrastructure safe. Most pyro devices have similar designs or design features. Hermetic sealing is used to protect a device from environmental intrusion. Corrosion protection is also a common design feature in pyro devices. It is important to consider human factors when designing parts so that it is not difficult to operate yet only functions when commanded. Mounting provisions and safe handling (safety pins, caps, plugs, shunts, etc.) are necessary to help protect the product, but also protect the people who are handling it.

Why Pyro Devices?

You may be wondering why pyro devices in the age of electronics? Well, pyro devices are very fast. In fact, we deal in microseconds and milliseconds. According to man-rated systems and other missile and space programs these devices need to be highly reliable. As a result, the manufacturer of CADs, PADs, and linear product must be very exact. In that exacting environment, we can produce products that have as many as three, four or five nines of reliability working at a very high confidence level. Most of these devices are small (some as small as 1” by 2”) but they pack a high level of energy. Lastly, pyro devices are used on a broad spectrum of applications. Quite literally, CADs, PADs and linear products are used from deep sea to deep space.

Energetics – Aerospace & Defense (A & D)

An energetic is a chemical material that contains reactive substances and a large amount of potential energy.

Primary Explosives

Primary explosives are initiated by friction, shock, or heat. At PacSci EMC, we use this energetic in many different places to start the explosive train. Examples of primary energetics include Lead Azide, Lead Styphnate, DBX-1 (a green replacement for Lead Azide), and KDNP (a green replacement for Lead Styphnate).

Secondary Explosives

Secondary explosives require a strong shock to initiate. Once initiated, they provide a shockwave and high pressure which travels at supersonic speed. Common highenergy explosives like HNS, PBXN-5, HMX, RDX and PETN are used in aerospace and defense and some commercial oil and gas operations.

Deflagrating Material

PacSci EMC also has deflagrating material which is an energetic producing a flame propagation and transfers heat and mass at a subsonic speed. Rapid Deflagrating Material (RDM) is proprietary to PacSci EMC and is used in transfer lines in aircraft systems to aide emergency escape. Other deflagrating materials include Auto-Ignition Materials (AIM), Time Delay Compositions and Ignition Materials.

Propellants

Propellants are chemical materials that produce gas byproducts to create thrusts. At PacSci EMC, the most common propellants are Ammonium Perchlorates and Ammonium Nitrates.

Cartridge Actuated Devices (CAD)

A Cartridge Actuated Device is a component that receives an input stimulus to initiate an internal cartridge providing an output to active explosives or other components. The inputs to initiate can be electrical, pressure, detonation, mechanical, or even LASER. Outputs can be electrical pressure, detonating, or mechanical. To do an electrical output, we use devices called Pyro Switches. When the switch is closed, power is allowed to run through. Other devices may use a chemical reaction within the CAD.

Features

CADs are an internal cartridge within a device housing and come in two types: instantaneous and delay. Instantaneous have a delay of less than 50 milliseconds to respond to any input stimulus. Other devices have a time delay that can be 0.17 seconds to 5 minutes or more sequencing a single series of events. MIL standards may also apply to some CADS. MIL-C-83124, MIL-C-83125, and MIL-D-21625 all apply to the internal cartridges themselves. MILSTD- 1472 applies to human factors. Most CAD designs are manufactured to contain all the by-products of combustion so that no one is exposed to any hazardous materials or can’t cause another catastrophic result, i.e., starting a fire.

Pyro Valves are designed with an open and/or closed feature. This design allows users to decide what the valve should do. Let’s say a liquid is free flowing going from Point A to Point B and in an emergency that liquid needs to shut off. Using a pyro valve that is normally open (allowing the flow of liquid) will very quickly shut off that supply when activated.

Thrusters, Actuators, Pin Pullers, and Retractors use energy to extend or retract a piston or pin.

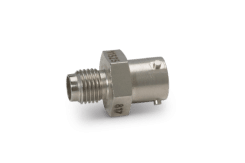

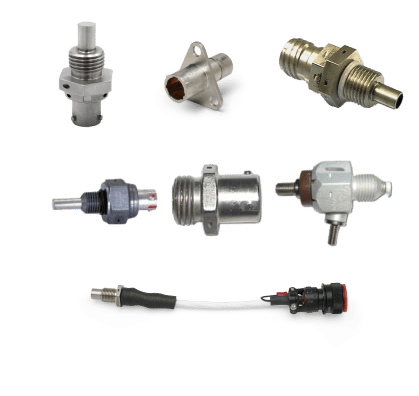

PacSci EMC produces several different types of CADs. Explosive Bolts, Cutters, Pyro Valves, and Pyro Switches. All of these can be used in a lot of different ways on many different programs. Additionally, all our devices in this image have either been on an aircraft, missile, or space platform.

Arm Fire Initiators (AFI) / Mechanical Pull Initiators

Arm Fire Initiators or Mechanical Pull Initiators are mainly used in emergency escape systems on military aircraft. Additionally, they have been used in some flight test commercial aircraft that also have an escape system. The yellow handle, on the C-17, is turned 90° left or right and then pulled. This is initiates the Flotation Emergency Deployment System (FEDS).

Separation Nuts

Separation Nuts are used in launch vehicles. Our largest to date operationally were on the Space Shuttle Program when it was active. Eight of these devices held down the entire vehicle to the launch pad before taking off on another space mission. We are using other versions for vehicles like Atlas or small deployment systems.

Electro-Explosive Devices (EEDs)

Electro-explosive devices can be argued as a subcategory of CADs. It’s a device that converts electrical energy into heat to initiate an explosive reaction. The input is electrical energy, and the output can be either a detonation or a pressure output.

Features

Normally, these devices are designed to MIL-DTL-23659. In some cases, for missile applications, MIL-STD-1512 requirements must also be followed. MIL-DTL-23659 provides a No-Fire level at 1 amp/ 1 watt to ensure safe handling. When handling a sensitive device with a low All-Fire level something as small as a little stray voltage from rubbing hands could set off the device. The All-Fire levels are set at a minimum of 3.5 amps, but at PacSci EMC we recommend that 5 amps is preferable to allow for a safety margin.

EEDs can initiate multiple types of devices. A Standard Initiator can go into a Pyro Valve, Pyro Switch, even a Guillotine or Cutter. There are many different functions for EEDs. They can initiate a single device or be used to act individually with their output performing the other function. With PacSci EMC Smart Energetics Architecture (SEA™), these devices can be digitally addressed. Our electronic systems allow an individual digital address to be assigned to each EED allowing it to fire based

on a specific input parameter. For example, that input could be from a navigation computer to a bank of small thrusters with these types of devices to steer a missile or spacecraft.

There are a variety of new and exciting things that the electronics world is opening, allowing us to introduce new technologies. An example of this is launching a large number of CubeSats or SmallSats from one launch vehicle. With this technology, it’s possible to sequence how they are launched to avoid possible collisions rendering them unusable. This technology helps mitigate such an event.

Pressure Cartridges:

This happens to be a pressure cartridge we provide to an ejection seat.

Catapult Initiator:

This device sets off the F-22 rocket catapult as part of the ejection system.

Smart Initiator:

This is the device mentioned in relation to our SEA™. Smart initiators have a little electronic board which is used to individually address that device. As a result, it can sequence different events that are all part of the same occurrence.

Detonators/Firing Squids:

These devices are used to open the supply bottles for fire suppressants.

Propellant Actuated Devices (PAD)

Propellant Actuated Devices are a normally compact envelope and utilize the energy supplied by reacting propellants to initiate a mechanical action. As an example, that mechanical action could be an Engine Start Cartridge, a Pyro Igniter, or a Gas Generator.

The inputs could be electrical, hot gas or mechanical. The output is normally a gas pressure but could also be a flame.

Features

Like CADs MIL-C-83124 and MIL-C-83125 apply to Propellant Actuated Devices.

At PacSci EMC, we use Ammonium Perchlorate (A), Ammonium Nitrate (AN), and Magnesium/Teflon/Viton (MTV) (also known an MagTeflon).

By-products of combustion are contained except at the output end, in other words the nozzle. Frequently, that pressure is used to start a small turbojet engine, light off a liquid fueled engine, or retract the straps of an ejection seat inertia reel pulling the pilot in an ejection seat back, placing them in a more optimal or better ejection posture.

Digital addressing for small rocket motor thrusters can be done using our SEA™. In this case, it might help to provide it as an attitude control module or to deorbit a SmallSat or CubeSat and get it back to Earth, thereby not becoming space debris.

Different types of PADs include Gas Generators, Igniters, and Small Rocket Motor Thrusters.

Mild Detonating Cord (MDC) / Mild Detonating Fuze (MDF):

Mild detonating cord fractures target material with detonation shock wave at the point of intimate contact.

Rapid Deflagration Cord (RDC):

For Rapid Deflagration Cord, we use an explosive transfer line. Currently, this line can be found in the F-35 Lightening II and the T-7 Red Hawk. RDC has been used in other applications on missiles, including as a small time delay because it’s a slower burning material that is well characterized.

Auto-Ignition Material Cord (AIMC):

Auto-Ignition Material Cord is used in our Thermally Initiated Venting Systems on missiles. It will automatically ignite if an unintended heat source is threating the rocket motor onboard a missile.

Features

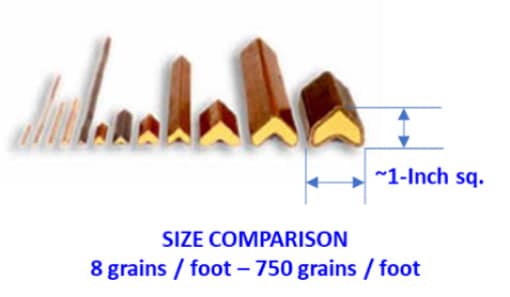

Common sheaths for linear explosives are copper, tin, aluminum, silver, and lead. Linear cord is measured in grains per foot (one grain is equal to about 0.065 grams of explosive material).

Velocity is used to understand how well the material is performing. The velocity is dependent upon the type of explosive material. For detonating HNS, the velocity is somewhere around 6,500 meters/second, but PBXN-5 can have a velocity as high as 8,300 meters/second. For Rapid Deflagration Cord the velocity is somewhere around 300 meters/second. The differences are there so customers can choose what they want on their system. For example, with a heavy shock it’s detrimental that a deflagrating material is used.

Expanding Tube Assembly (XTA)

Expanding Tube Assembly consists of a Mild Detonating Cord (MDC) installed in a rubber ribbon and into an oval shaped metal tube .

It is designed in a shear joint that can cause metal to sever along a designated line or acrylic to fracture along a line of bolt holes. When the MDC goes off, the oval shape of the XTA is reshaped into a round configuration resulting in a force to break along a predetermined separation plane.

Time Delay Initiators (TDI)

Time Delay Initiators provide a means of delaying or sequencing events in a system using proprietary delay composition. At PacSci EMC, we extrude our TDI’s into a metal sheath called Small Column Insulated Delay (SCID). It is placed in the cartridge and into the initiator body.

Linear Explosives

Linear explosives are basically explosive powder or material that’s drawn in a continuous metal sheath. Inputs for a detonating material need to be another detonation or high shock. For deflagrating type materials in a metal sheath, it should be a detonation, flame, or heat input. Outputs will be detonation shockwave for Mild Detonating Cord (MDC), Mild Detonating Fuze (MDF) and Linear Shaped Charges (LSC). Rapid Deflagrating Cord (RDC) and Auto-Ignition Material Cord (AIMC) material would have pressure or a flame as outputs.

Basic Types Manufactured

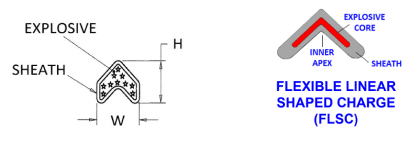

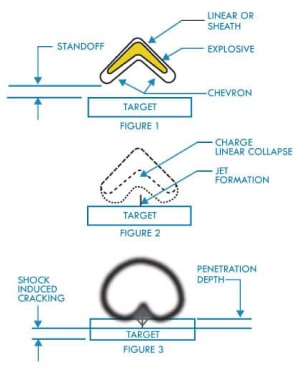

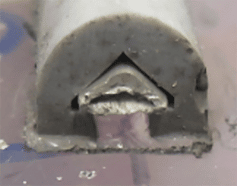

Linear Shaped Charge (LSC) / Flexible Linear Shaped Charge (FLSC):

Linear Shaped Charge (LSC ) and Flexible Linear Shaped Charge (FLSC ) charge utilize a function described by the Monroe effect.

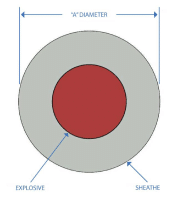

This image shows the Monroe effect with a target underneath and a piece of linear shape charge. The explosive in the middle and the shaped charge sheath could be silver, copper, lead, tin or even aluminum.

The target is located underneath. A standoff allows the formation of a jet in the center picture. This is going to develop when the explosive material initiates and the inner core (or inner apex) collapses in on itself.

The jet, composed of metal flakes and high heat, then hits the target creating a penetration. In some cases, the charge is sized to do a 100% severance. In other cases, it may only be sized for 70% and a shockwave will induce a fracturization or pulverizing of the target material to break it the rest of the way.

Sub-Assemblies / Higher Assemblies

Severance Assemblies:

Severance assemblies include Linear Shaped Charge (LSC) and Flexible Linear Shaped Charge (FLSC).

They are used for cutting windows on an airplane or as a destruct charge. Targets include steel, aluminum, composites, acrylic (stretched or cast), polycarbonate, and laminate.

Fragilization Assemblies:

Fragilization Assemblies include Mild Detonating Cord (MDC )

It is used for canopy fracturing systems or even separation events. Targets include aluminum and acrylic (stretched or cast).

Explosive Transfer Lines:

PacSci EMC produces 5 different types of explosive transfer lines.

The only deflagrating

line we produce is Rapid Deflagrating Cord Transfer Line (RDCTL) which is a stand-alone product. This line can incorporate a percussion primer as well as a lower energy output. Shielded Mild Detonating Cord

(SMDC), Flexible Confined

Detonating Cord (FCDC), Flexible Detonating Cord (FDC), and Confined Detonating Cord (CDC) are all detonating lines with a much higher detonation velocity (as described earlier). All our detonating lines have high-energy end fittings. It requires a detonation or high shock to initiate it and, as a result, provides a detonation output.

Mild Detonating Fuze (MDF)

Mild Detonating Fuze is commonly used in initiation explosive trains and is very similar to MDC, but it has more exacting requirements.

RDC Fuze Initiation Train

RDC has been used in a Fuze Initiation Train where only a deflagration is required, and a detonation is not. Its high reliability of ignition when commanded makes it an excellent candidate for certain applications i.e., shoulder fired missiles.

Specialty Devices

Specialty Devices receive an input stimulus after ‘ARMING’ command and provide output signals especially for Ignition Safety, Arm Fire and Safe Arm Devices (ISD, AFD and SAD). These highly specialized devices are predicated on functioning only when commanded for applications like rocket motor ignition or flight termination system activation. The inputs are electrical, and the outputs are detonating, electronic signal, or laser.

Features

Specialty devices are either electromechanical or electronic. Depending on the use, MIL-STD-1901A/1316 and RCC-319 are considered when designing and qualifying the device. For an all-electronic device pyrotechnics are ‘Out-of-Line’ until ‘ARMED’ by mechanical means or electronic inhibits.

Types

Different types include Ignition Safety Devices (both Electromechanical and Electronic EISDs) and Arm Fire Devices (AFD/eAFD) for rocket motor ignition. Safe

Arm Devices and Safe Arm Fire (both Electromechanical and Electronic) are used in flight termination and thrust termination assemblies.