DOUBLE-BASE PROPELLANT DECOMPOSITION

Failure investigation identified decomposition of Nitrocellulose/Nitroglycerine (NC/NG) double base propellant used in Bullseye propellant. This occurred during temperature cycling where the temperature was held at +95°C (+203°F) for 16 hours.

Robert Weinheimer, Bill Sanborn

Published: 29th International Pyrotechnics Seminar

Table of Contents

Abstract

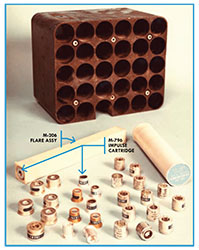

The U.S. Army impulse cartridge M-796 and U.S. Air Force BBU-35B are used to eject countermeasure stores (flares and chaff) from aircraft dispensers (XM-130, ALE-40, ALE-45, ALE-47) of military aircraft (F-16, F-15, A-10, C-130, AH-64, MH53E, and CH-47). Both the M-796 and BBU-35B impulse cartridge are of the same general configuration with different part numbers for the Army and Air Force. Both are used to eject a M-206 Infrared Flare.

The M-796 and BBU 35B are subjected to temperature-altitude conditions and aircraft flight, ground and maintenance environments (-62°C/-80°F to 95°C/203°F) during qualification and acceptance tests.

The M-796 and BBU-35B use a double base NC/NG propellant for producing gas pressure against the countermeasure piston for ejection (and to ignite a Mg-Teflon flare) from the aircraft dispenser. In 1978 the double base propellant (Bullseye), U.S. Army drawing 9326769 (USAF drawing 7829435), was used in the impulse cartridges M-796, USA 9311660 and BBU-35B, USAF 7729436.

During qualification testing, the M-796 impulse cartridge had experienced inconsistent function time and pressure rise time (psi/ms slope) failure mode. The failure occurred after exposure to Temperature–Altitude test per the customer’s procurement specification tailored from MIL-STD- 810, Method 504.1.

Failure investigation identified decomposition of the Nitrocellulose/Nitroglycerine (NC/NG) double base propellant which occurred during temperature cycling where the temperature was held at +95°C (+203°F) for 16 hours.

This paper describes an empirical investigation test method used to determine the failure mode and discusses the test results.

MH53E Sea Dragon Helicopter Infrared Flare Deployment

In 1978 during qualification of the M-796 Impulse Cartridge (9311660), inconsistent ignition time and pressure vs. time rise rate was experienced. The cartridges had completed an environmental temperature-altitude cycling per customer requirements as follows:

1. Set chamber at -62°C (-80°F) and expose cartridges for two (2) hours minimum

2. Set chamber at –54°C (-65°F) and expose cartridges for two (2) hours minimum

3. Set altitude chamber at 60,000 ft altitude and expose cartridges for 30 minutes

4. Set altitude chamber to laboratory ambient altitude at –10°C (+14°F) and let cartridges stabilize

5. After cartridges have stabilized, open chamber door and allow frost to form. Leave door open long enough to allow the frost to melt but not evaporate.

6. Set chamber to +95°C (+203°F) ambient altitude, and maintain for sixteen (16) hours minimum

7. Set the chamber to +71°C (+160°F) and ambient altitude

8. After stabilization record thermocouple readings

9. Set chamber to +95°C (203°F) ambient altitude, and maintain for 30 minutes

10. Adjust the chamber condition to +71°C (+160°F) and ambient altitude. After the chamber condition has stabilized maintain for one (1) hour. Adjust chamber temperature to +101°C (+214°F) and maintain for 20 minutes. Record thermocouple readings every 10 minutes. Repeat this step for two (2) additional cycles.

11. Set the chamber to +24°C (+75°F) and allow chamber to stabilize. Adjust the altitude to 60,000 feet. Maintain for four (4) hours. Record the thermocouple reading every 30 minutes.

12. Change the chamber temperature to +83°C (+181°F). Allow the chamber to stabilize thermally and maintain for 2 hours.

13. Stabilize the chamber at +36°C (97°F). After stabilization, maintain for one hour. Change chamber temperature to +143°C (+289°F) and maintain for 10 minutes. Then set the chamber temperature to +70°C (+158°F). Record temperature every 10 minutes. Repeat this step two additional times. Return chamber to ambient conditions.

14. Inspect the squibs for any damage caused by the temperature-altitude test. Document all observations.

Bulging of the closure disc was noted after Step 6. [temperature at +95°C (203°F) for 16 hours].

Upon completion of the Temperature-Altitude test the cartridges were subjected to functional testing at ambient. During the functional test inconsistent ignition time and pressure vs time rise rate was experienced.

Double Base Propellant NC/NG Investigation

The double base composition of Bullseye was suspect. Discussions with Hercules of the inconsistent function time and pressure rise rate revealed that +95°C (+203°F) was too severe for any NC/NG double base propellant. Hercules recommended not to expose Bullseye to temperature extremes greater than +75°C (+167°F) for extended lengths of time. Hercules also recommended using one of their high temperature propellants [Hi-Temp (RDX) or 8028 (HMX)] for this application.

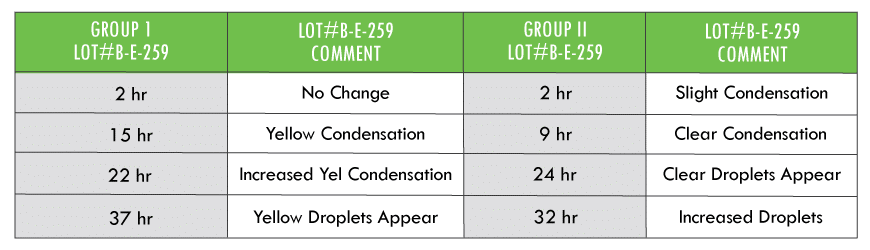

An empirical temperature test was performed with two different lots of Bullseye, Lot# B-E-259 and B-E-269. Bullseye propellant was weighed and sealed in ten glass vials. Five vials contained 195 mg each of Lot# B-E-259 and five vials contained 195 mg each of Lot# B-E-269. The two groups (lots) were placed in an environmental chamber and the temperature was set at +85° ±2°C (+185° ±4°F). Periodic observations were made over time.

To eliminate water moisture as the observed condensation, five additional glass vials were wetted with water droplets and set alongside the unsealed Bullseye samples. The vials were left for six hours unsealed at ambient temperature.

RESULTS: The vials wetted with water droplets had dried while the Bullseye vials still had the condensed droplets.

CONCLUSION:

1. A colorless to yellowish substance condenses on the glass vial when the Bullseye is exposed to +85°C (+185°F).

2. The condensation on the glass vials containing Bullseye is not water.

3. There is a difference in the color of condensation/droplets between the two lots of Bullseye.

4. The condensation/droplets are most likely decomposition of the Bullseye propellant.

5. The condensation though not quantitatively identified is most likely Nitroglycerine.

Impulse Cartridge Investigation

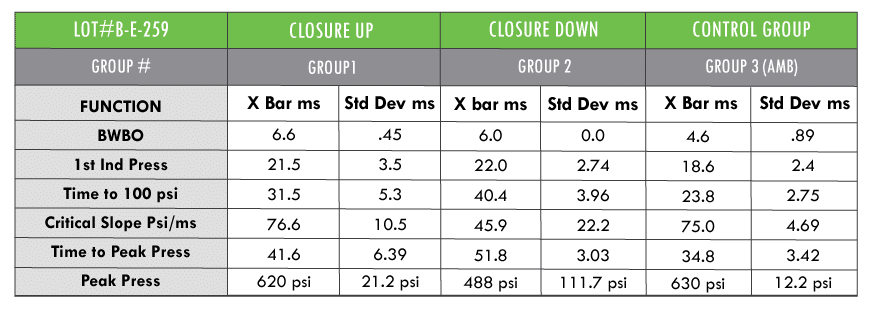

Thirty M-796 cartridges were assembled with Bullseye propellant, fifteen contained Bullseye designated as Lot #B-E-296 and fifteen designated as Lot #B-E-259. The cartridges were then divided into six groups, three groups each lot, five cartridges each group, Group #1, #2, & #3 were of Lot #B-E-269, Group #4, #5, & #6 were of Lot #B-E-259. Groups #1 and #4 had the cartridge oriented in the environmental chamber with the closure end up. Groups #2 and #5 had the cartridge oriented in the environmental chamber with the closure end down. Group #3 and #6 are ambient control groups. The orientation of the closure, up vs down, was to see if convection within the cartridge might be factor.

The cartridges were subjected to an elevated temperature of 85°C ±2°C for 21 hours then functioned at ambient in a closed volume (45cc).

CONCLUSION:

Based on visual examination of the cartridges and test firing data the following conclusions are supported.

1. The elevated temperature of +85°C (+185°F) affects cartridge performance.

2. Cartridge exposure at +85°C (+185°F) will cause internal pressure to bulge the closure.

3. There appears to be different functioning characteristics between lot numbers when comparing Group 2 to Group 5.

4. Cartridge orientation during +85°C (+185°F) exposure appears to have an affect on functioning characteristics.

Summary

The decomposition of the Bullseye does not render the propellant inert but the condensation/droplets likely permeates the bridgewire ignition composition and booster charge (BKNO3) thereby affecting chemical reaction, thus performance. This is indicated by the long ignition time and inconsistent pressure vs time rise rate. It is important to note that at no time did a failure to function occur.

As a result of the above investigations, HPC-1 (10534810) replaced the Bullseye in the M796. And HMX (8412690) replaced Bullseye in the BBU-35/B-20. There have been no known anomalies with ignition time and PvT rise rate performance of the impulse cartridge since using the high temperature propellant output charge.

The BBU-35/B-20 (HMX) currently meets Detail Specification SP-7729436B call out for an operating temperature range of -54°C (-65°F) to +85°C (+185°F).

RECCOMENDATION:

Avoid the use of NC/NG double base propellant in defense/aerospace applications that have environmental requirements above +74°C (+165°F).

Technical Discussion

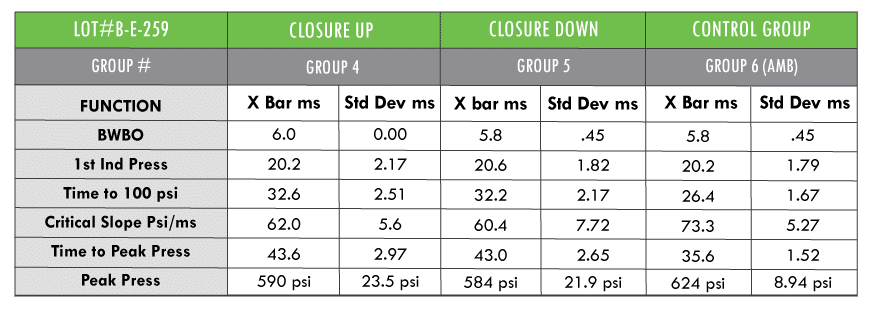

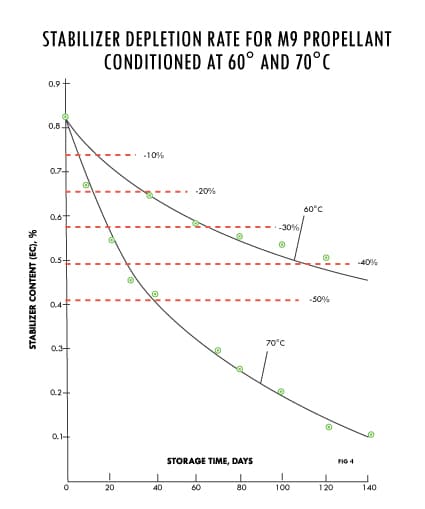

N. S. Garman, et al, ‘Prediction of Safe Life of Propellants’, Picatinny Arsenal, May 1973, reported on M9, NC/NG propellant, chemical stability under accelerated aging at elevated temperatures. The propellant M9 was tested and its composition is compared to Bullseye (UASF 7829435 & USAARDC 9326769) and HPC-1 (USAARDC 1053481):

*While HPC-1 is a NC/NG double base propellant it meets the operating temperature range of -18°C (-65°F) to +85°C (+185°F). The ethyl centralite (stabilizer) is twice that of Bullseye and M9 propellant which would improve the temperature tolerance of the HPC-1 NC/NG composition.

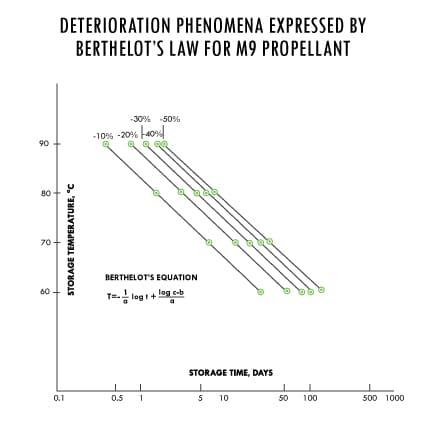

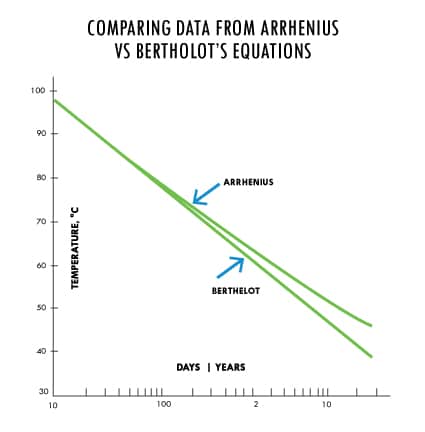

Figure 1 and 2 show the depletion rate of the stabilizer (ethyl centralite) over time for +60°C

(+140°F), +70°C (+158°F), +80°C (+176°F) and +90°C (+194°F) for M9 propellant.

Figure 1: Stabilizer (Ethyl Centralite) Depletion for M9 Propellant (N.S. Garman et al, Prediction of Safe Life of Propellants)

Figure 2: Deterioration Phenomena Expressed by Berthelot’s Law for M9 Propellant (N.S. Garman et al, Prediction of Safe Life of Propellants)