System Reliability Summary

Reliability is always desired, but it becomes essential when safety and mission success are at stake. System failures can have a direct and negative impact on time, budgets and reputations. They can also cost human lives.

Redundant, backup systems are often used to reduce the probability of failures. But they are not always viable, as certain systems cannot accommodate the additional space and weight of redundant components. In these cases, reliability must be built into the system.

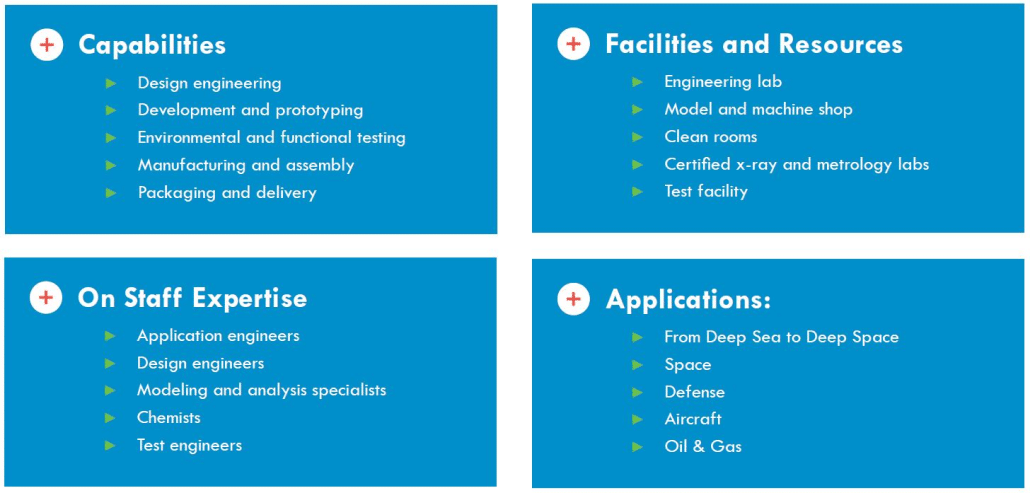

We are experts with systems reliability, safety and quality. As an integral contributor to countless space, defense, aircraft and oil and gas programs, our long history of success is largely built on the reliability and safety of the solutions we create, customize and deliver.

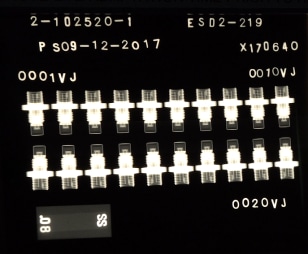

We bring a scientific approach to every project, calculating system reliability through trade studies, mathematical modeling, in-depth analyses and rigorous testing. Our application engineers can identify solution possibilities, weigh them against a number of variables—including mission criticality, space, weight and cost—and calculate reliability scores for each. Many of our materials, devices and solutions deliver 99.999 percent reliability or better.

We can customize or create a solution that meets your reliability, safety, functionality and mission criteria. Every time.

Calculating Reliability

We use a variety of methods to calculate system reliability, including trade studies, mathematical modeling, indepth analyses and rigorous testing.

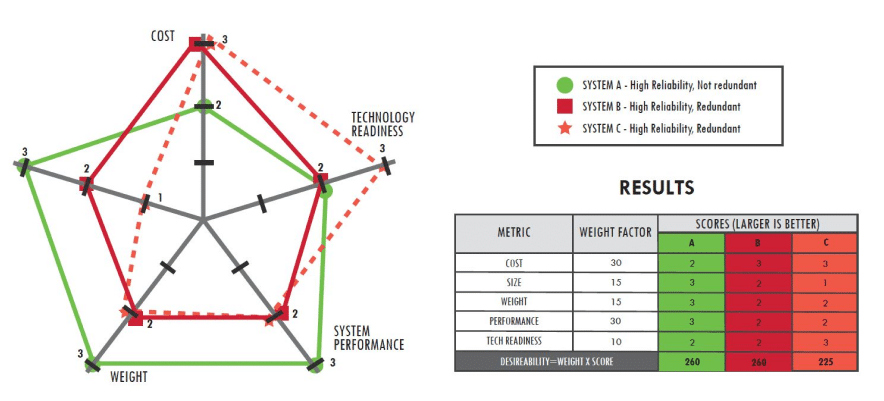

A trade study is often the first step, with systematic analysis of the relationships between factors such as mission criticality, space, weight and cost in the context of a particular application. These factors form the elements of the trade study matrix and are weighted based on the system application. The trade study then assigns various potential design solutions a score based on how well they satisfy all the factors.

Our engineers can also conduct in-depth Failure Modes Effects and Criticality Analysis (FMECA), which takes the investigation assessment down into individual components that make up the subassemblies, assemblies, components and overall system reliability.

The Trade Study Matrix

Trade studies are used to evaluate and compare potential concepts or systems for a particular application. The matrix below shows three concepts that will meet the customer’s reliability requirements. To select the best option, the concepts are scored against five key parameters. Each parameter has a weight, or importance, factor that was determined prior to the evaluation. The concepts are quantitatively evaluated by multiplying the weight factor by the score and then summing each parameter. The system with the highest score wins the trade study. In this example, System A is the clear winner.