A story of how space technology can be extrapolated into something soft, warm and wearable.

When Michael Markesbery, future cofounder of Oros Apparel, climbed the tallest mountain in the Swiss Alps with friends, he was bundled up with so many bulky layers he could barely move his arms. Without knowing it, something already existed that could make incredibly warm outerwear with far less bulk, and it owes much of its development to NASA.

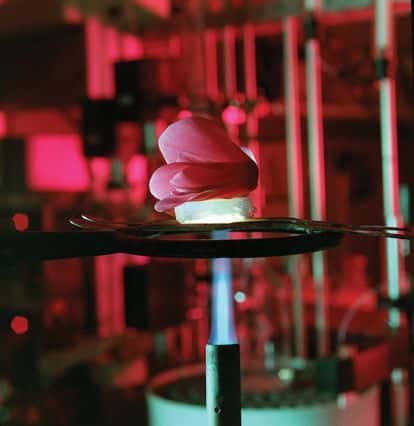

The material, silica aerogel, was first invented nearly 100 years ago, before the Space Agency was founded. Aerogels are a class of materials that are made by creating a kind of gel and then removing all the liquid through a process known as supercritical drying, leaving a porous solid filled with air.

When made out of silica, or fused quartz, the resulting material has pores less than one-ten thousandth the diameter of a human hair, or just a few nanometers.

That nanoporous structure gives silica aerogel the lowest thermal conductivity of any known solid, which means it’s an incredibly good insulator, and because the structure is 95 percent air, it is also extremely lightweight.

The possible applications for the material were obvious, but pure silica aerogel had a pretty major downside. Silica, one of the key ingredients in glass, is brittle: as an aerogel, it would crack under the slightest pressure. So for decades, silica aerogel was hardly ever used. NASA helped change that.

In 1992, Kennedy Space Center’s James Fesmire, the mechanical engineer responsible for managing cryogenic propellant systems design at the launch pads, had an idea for a flexible aerogel insulator—a composite with the same ability to stop heat as traditional silica aerogel but one which would solve the brittleness problem. He wanted to use it to insulate the equipment that stored and transferred liquid fuel for the Space Shuttle, which needed to be kept at temperatures hundreds of degrees below zero.

The following year, Kennedy awarded a Small Business Innovation Research (SBIR) contract to Aspen Systems Inc. to work on creating that flexible, durable, easy-to-use form of aerogel. The company soon developed aerogel composite blankets that fill the spaces of a fiber web with silica aerogel. Further SBIR contracts and partnerships helped prove the excellent insulating characteristics of the new composite material and improve manufacturing practices to make it cheaper and faster to produce.

Aspen saw that it had a marketable product and spun off a division called Aspen Aerogels Inc. to sell its flexible aerogel commercially. This NASAdeveloped technology is used to insulate spacecraft at -450°F. Used for its cryogenic fuel tanks and pipelines, and elsewhere in other formulations, but the material has also found many applications outside the space industry, including building and construction, appliances and refrigeration equipment, and more.

All of this development happened well before Markesbery summited in Switzerland, but he didn’t find out about aerogel until several years later, when he won a scholarship from the Astronaut Scholarship Foundation for his undergraduate research.

As part of the award, Markesbery got to meet NASA personnel, including astronaut Robert Gibson, from whom he finally learned about the material. Intrigued, he remembered his problem with bulky layers and wondered if this could apply to clothing and apparel.

Ultimately, he and his partners launched a Kickstarter campaign (featuring a video of Gibson), and started selling the brand new company’s first product: the Lukla jacket, insulated with Aspen’s aerogel blankets. They quickly raised more than $300,000 and sold more than 1,100 jackets, all featuring the aerogel blankets developed with NASA funding.

The company continued its research and ultimately came up with a new, proprietary way to utilize aerogel in a flexible polymer composite, which it says provides more structure and stability than the fiber blanket. It also increases breathability for comfort and reduces the overall weight of the insulation. As a result, the next generation jacket is at least 40 percent lighter than the original, weighing in at just 2.5 pounds or less. Developed in 2016, this new, proprietary insulation was called SolarCore. Since then Oros has extended its product line to include gloves, leggings, snow pants, and base-layer shirts. Even the knit hats are insulated with SolarCore, which is knitted into the brim.

The original product line and core inspiration for development started with aerogel’s NASA roots.

WAYS SPACE TECHNOLOGY HAS IMPACTED LIFE ON EARTH

What do you do when you need to monitor the health of astronauts who are hundreds of miles away from the Earth? That’s the question that NASA scientists and engineers faced as they sent astronauts into space. And the solution they came up with has made diagnosing diseases incredibly easy. This invention, along with a long list of other tech advances, has forged a link between the importance of space exploration and everyday life.

Nanosensor Array for Medical Diagnoses

What do you do when you need to monitor the health of astronauts who are hundreds of miles away from the Earth? That’s the question that NASA scientists and engineers faced as they sent astronauts into space. And the solution they came up with has made diagnosing diseases incredibly easy. This invention, along with a long list of other tech advances, has forged a link between the importance of space exploration and everyday life.

Nanosensor Array for Medical Diagnoses

NASA’s attempt to come up with a diagnostic test for astronauts resulted in a compact device worn on the head that is an ingenious cross between a breathalyzer and a testing array. Its nanosenor array is ingenious, in fact, they claim “no such technology exists in the market today.”

The technology boils down to a single nanosensor array chip. The chip uses chromatography mass spectrometry to assess the chemical composition of human breath, thereby finding markers for certain diseases like Type I diabetes. NASA has made the technology available for licensing.

The ResQPOD

A heart attack happens every 40 seconds in the United States. Most people who have a heart attack die before they walk through hospital doors.

Enter the ResQPOD, a CPR device that increases blood flow and can reduce

death rates and, by sending oxygen to the brain, decrease the chances of neurological damage from cardiac arrest. NASA developed the device as it

tackled blood pressure issues that are common among astronauts returning to

Earth. The result is a simple device that paramedics can use to sustain a patient during transport to a hospital.

According to NASA, its ResQPOD has worked so well in some cities that

patients have up to a 50% better chance of making it to the hospital after a heart attack.

Memory Foam

Over the past 10 years, memory foam pillows and mattresses have flooded the market. As recently as 2018, the industry was worth more than $80 billion.

All those consumers who fall asleep on the form-fitting, cool-sleeping, silent mattresses and pillows can thank NASA for their sweet sleep

According to NASA, they developed memory foam (also known as “temper foam”) in the 1970’s because they wanted “to improve seat cushioning and crash protection for airline pilots and passengers.”

Top-notch Radial Tires

Also in the 1970’s, NASA was looking for a way to create virtually indestructible tires that could provide a soft landing for its Viking 1 and 2 missions. So, they worked with Goodyear to come up with a solution. That solution was a tire material that was five times stronger than steel.

“The fiber’s chain-like molecular structure gave it incredible strength in proportion to its weight,” NASA notes.

Goodyear took that technology and applied it to consumer tires, creating a radial tire that could add 10,000 miles of tread life to the existing standard.

The partnership between NASA and Goodyear has continued. One of the partnership’s more recent successes was the development of a spring tire made from 800 load-bearing springs.

Crop Prediction

Most folks don’t know that predicting crop yields takes a lot more technology than opening up a farmer’s almanac. In fact, one of the most effective crop prediction systems started with Landsat 1, the satellite that entered orbit in 1972. NASA used the satellite to take hundreds of thousands of photos of the Earth.

Over the next couple of decades, NASA developed its Landsat imaging technology, eventually pairing it with its Moderate-Resolution Imaging Spectroradiometer (MODIS).

TellusLabs recognized the value of the data NASA imaging tech produced, and they started to pair it with various weather models and historical data to create crop predictions, a NASA write-up points out.

TellusLabs called its crop prediction product “Kernel” and launched it in 2016. According to NASA, Kernel “projected yields on 2016 U.S. soy crops within 1% of the final yields” two months before the U.S. Department of Agriculture.

What’s Next?

We’re proud of the work we do at PacSci EMC, not only because we know our technology helps achieve mission- critical results, but also because we know the missions of today will have global applications in the years to come.