MTX-1 | THERMALLY STABLE TETRAZENE REPLACEMENT

Tetrazene (1-amino-1(1H-tetrazol-5-yl)-azo-guanidine hydrate) is widely used in ordnance systems as a sensitizer of primer mixes for use in both percussion and stab applications. It has low thermal and hydrolytic stability compared with other components of primer mixes and there currently exists the need for a replacement with enhanced stability characteristics.

John W. Fronabarger, Michael D. Williams, Alfred G. Stern, and Damon A. Parris

“MTX-1 A Potential Replacement for Tetrazene in Primers”

Published: Central European Journal of Energetic Materials, 2016

A New Sensitizer with Improved Thermal Stability

There is a need to develop a new “tetrazene-like” sensitizer with improved thermal stability for primers used in normal or high temperature applications. MTX-1 has chemical and output properties combined with high friction and impact sensitivities that suggests its potential as a high stability tetrazene replacement.

Current primer mixes, such as NOL-130, are generally comprised of basic lead styphnate 40%, lead azide 20%, barium nitrate 20%, antimony sulfide 15% and tetrazene 5%; however, mixes containing a variety of other components are well known. The NOL-130 composition is relatively insensitive to stab initiation when the tetrazene component is omitted and addition of ≥ 2% tetrazene is currently a requirement to ensure high sensitivity. Tetrazene suffers from a number of issues, most importantly low thermal and hydrolytic stabilities. It has been demonstrated that tetrazene readily decomposes at ~90ºC, which is in the temperature range that may commonly be encountered during storage and handling. Tetrazene has also been shown to be susceptible to hydrolytic decomposition and is destroyed simply by addition to boiling water. As a result, it is clear that there is a need to develop a new sensitizer with improved thermal stability for primers used in normal or high temperature applications. In light of current environmental concerns, it would also be beneficial to generate this new material both cheaply and without the use of toxic materials as reactants or effluents.

MTX-1 Characteristics:

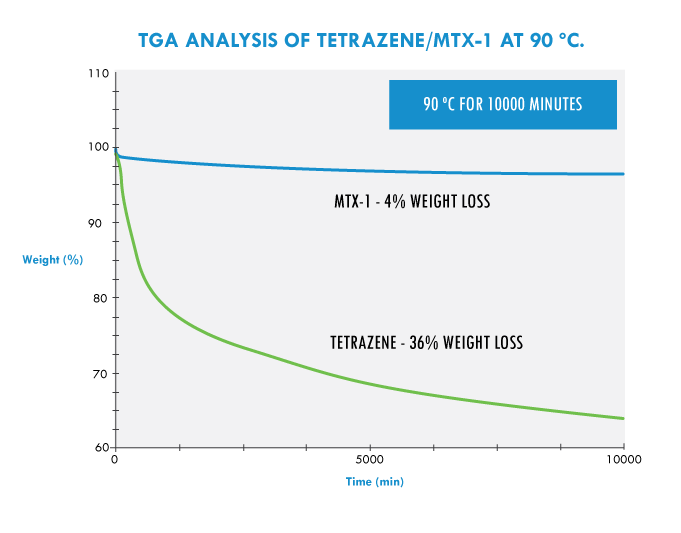

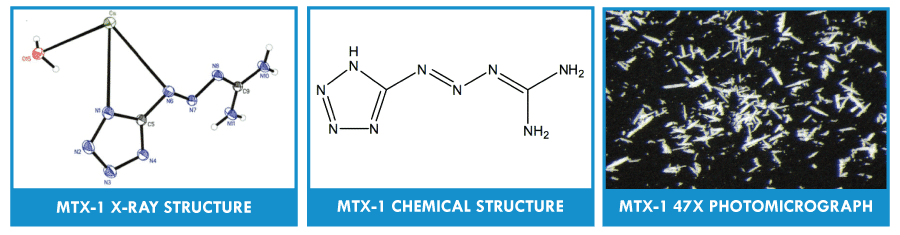

Pacific Scientific Energetic Materials Co. (PacSci EMC) in Chandler, AZ, in conjunction with the Office of Naval Research, has recently been involved in a program to develop existing or new materials which would serve as replacements for tetrazene and which have improved thermal and hydrolytic stability while maintaining the high sensitivity levels required. PacSci EMC has completed initial testing on a variety of compounds and has identified a new material which meets these qualifications. This material, MTX-1, is easily and inexpensively prepared from tetrazene in one step in aqueous solution. Side by side TGA studies on tetrazene (DSC exo 144°C) and MTX-1 (DSC exo 214°C) demonstrate that at 90°C, tetrazene loses 36% by weight over 167 hours while MTX-1 loses only 4% during the same time period. In addition, it has been determined that after exposure to water for ~120 days, MTX-1 may be re-isolated unchanged and in nearly quantitative yield. Most importantly, MTX-1 has safety characteristics (impact, friction, ESD) which are comparable to those of tetrazene and provides nearly equivalent (ball drop) sensitization of 95% BLS mixes when compared to identical mixes made with tetrazene. Although the crystal habit of MTX-1 is already very similar to that of tetrazene, additional process modifications may provide a larger (and more sensitive) morphology. MTX-1 is currently under investigation at PacSci EMC as a research and development material.