BURN, CUT, INITIATE,

SEQUENCE, SEPARATE, TERMINATE

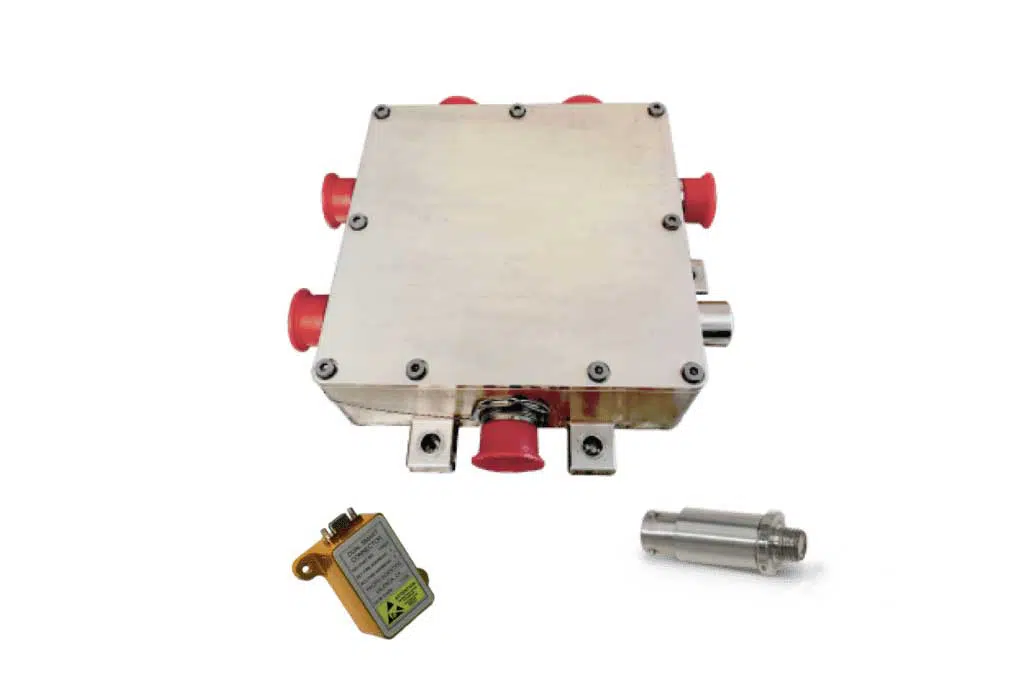

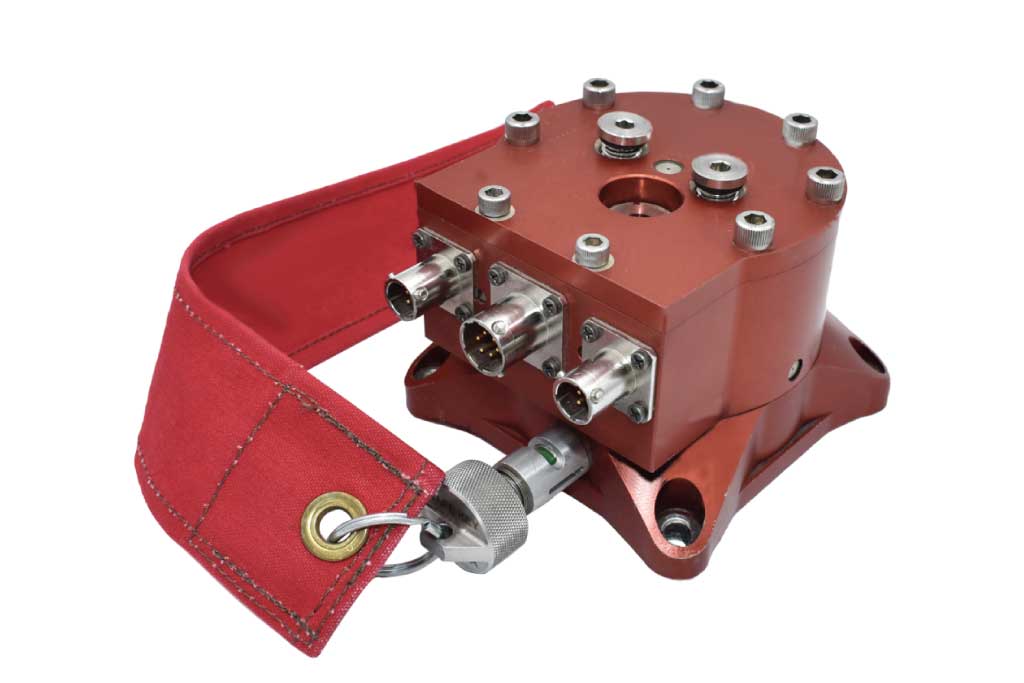

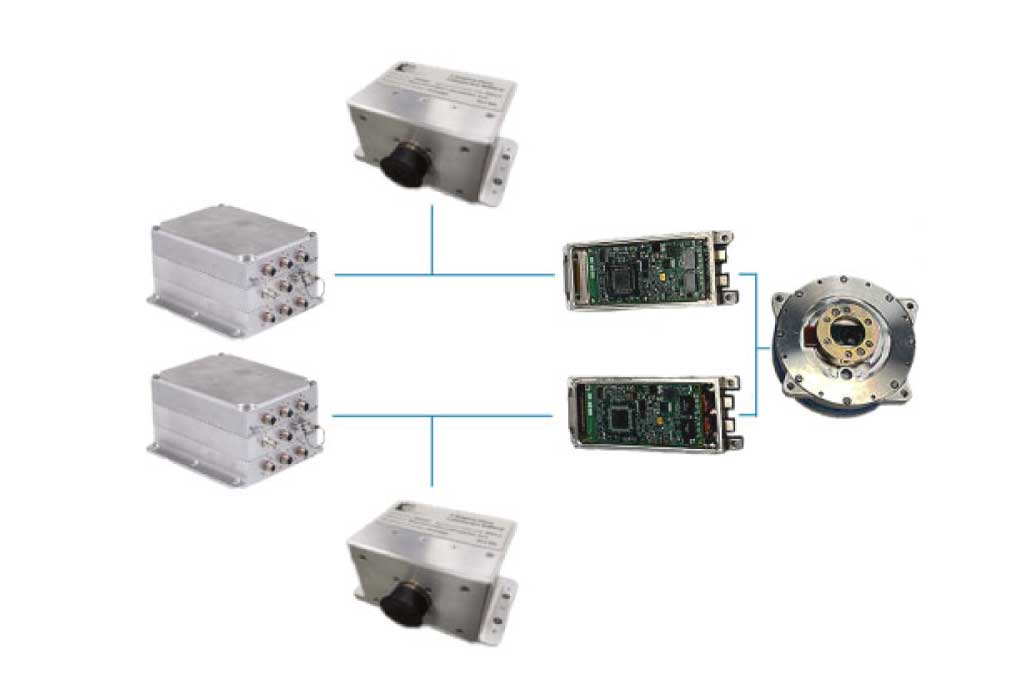

We ignite your motors. We sequence your events. We hold down your launch vehicles. We release your satellites. We sever your cables. We jettison your canopies. We remove the windows in your bird (even when underwater). We protect your pilots, crews, and civilian populations. We’ve been a part of saving lives for more than 70 years.

LOOKING FOR PYROTECHNIC AND ENERGTIC PRODUCTS?

Here are links to the most requested products we design and manufacture for programs around the world. By all means this is not an all-inclusive list of our products, to view all of our product capabilities please visit this page.

What can we help you find?

Energetics in Action

Get Connected

Stay current on industry trends, engage in conversations about our work, explore employment opportunities and more. Join us on LinkedIn, YouTube, Facebook, Twitter, and other networks to find out what is happening at PacSci EMC!

Join Our Team

We’re using energetics to save lives – we can’t accomplish this without the best and brightest talent.

Search the current opportunities to find a place for you.