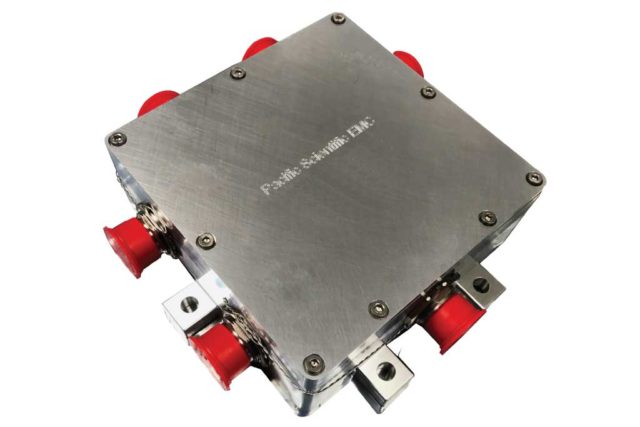

SEA™ Interface

Product Description

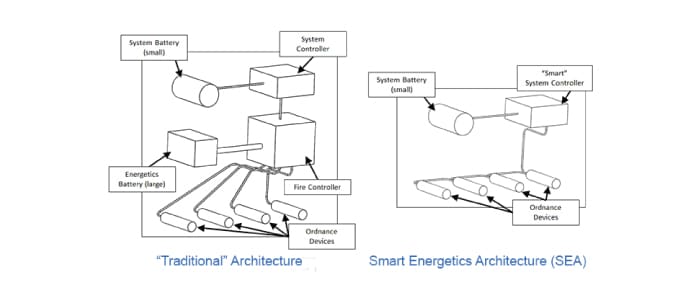

Our SEA™ Interface is a “Smart” low power networked ordnance command & control architecture containing smart pyro devices & digital sequencing

- Built-in-Test (BIT) improves reliability & helps ensure mission success

- Eliminates bulky cabling and heavy, separate ordnance batteries

- Compatible w/existing avionics systems

SEA™ Interface is derived from high reliability automotive safety technology – blending COTS, Auto & Aerospace capabilities. and inherently affords a huge savings in weight, power and wire complexity over the more traditional dedicated ordnance batteries and individually wired devices. Compatible with existing avionics systems, SEA Technology architecture can provide a variety of electrical signals and pressure outputs, enabling the system integrator to incorporate very robust diagnostics and health monitoring features in retrofit and design update applications as well as new system design.

Key Features

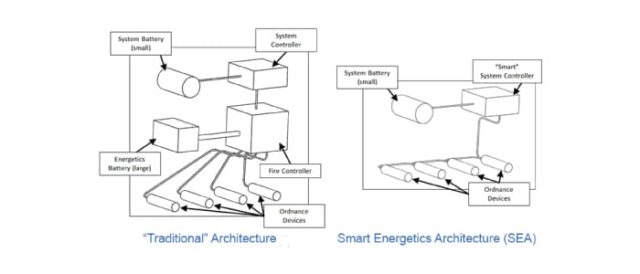

How Smart Energetics (SEA) Works

The increasing complexity of ordnance systems with multiple initiation devices force designers and system integrators to utilize digital architecture and bus systems. However, the criticality of mission success and man-rated systems demands the system have the same reliability as the traditional, discrete, passive systems. Pacific Scientific developed a networked ordnance control system by piggybacking on $10M development in the automotive industry for airbag initiation and seat belt retention. Called “Smart Energetics Architecture” (SEA™) Technology, it utilizes an FPGA and a proprietary ASIC modified for military applications arranged in a master/slave architecture to enable wiring up to 48 ordnance devices on a single bus. It is capable of providing data for health monitoring and diagnostics and also power to fire the devices. Each of the ordnance device assemblies has an ASIC circuit and firing capacitor built in, which reduces the required system power, eliminates the need for heavy wiring and high currents, drastically reduces EMI, and eliminates the need for a separate large power source to drive the required firing current. The key to incorporating the ASIC into the ordnance device is size, and the slave ASIC circuit is small. PacSci EMC has built ordnance devices incorporating the SEA ASIC on all the common initiator platforms, including TFB, EFI, SCB, resistorized detonators and bridge wire.

Applications

SEA™ Technology has been successfully incorporated in several attitude and divert control systems for missiles, satellites and projectiles, event sequencing of aircraft emergency egress systems, gun sequencing in hydraulic fracturing operations, space launch and separation events. It is flexible enough to be incorporated into proof of concept programs and it is mature enough for qualification in advanced programs.

SEA Technology has had over 10,000 firings in addition to many flight tests and has been successfully demonstrated on many programs

- Compact Kinetic Energy Missile (CKEM)

- Kinetic Energy Active Protection System (KEAPS)

- Long Range Countermeasure (LRCM)

- Mars Lander Program

- Miniature Multiple Kill Vehicle (MMKV)

- Patriot Advanced Capability-3 (PAC-3)

- Precision Guided Mortar Munitions (PGMM)

- Short Range Countermeasure (SRCM)

SEA™ Interface Capabilities

SEA™ Technology is ideal for complex, high-reliability systems. SEA™ Technology can handle the most complex systems, with features that include:

- Up to 48 devices per bus

- Capability to fire up to 12 devices simultaneously

- Bus length of up to 40 meters at maximum frequency

- Single command speed as fast as 150 µs

The communication to the controller of the SEA™ bus is customer-specified (through the FPGA), so integration is transparent for both new system design and retrofit/redesign applications. The building blocks of a SEA Technology solution can include:

- Smart Bus Controller (contains the FPGA and SEA Bus Driver)

- Smart Initiator: Provides output equivalent to a NASA Standard Initiator (NSI) and can be tailored according to requirements.

- Smart Detonator: Provides output and size equivalent to PacSci EMC standard Detonators

- Smart Connector, Single or Dual: Provides the ability to interface legacy ordnance devices with SEA Technology

- Smart Thruster: Provides fast reacting, energetic burst of energy to affect a controlled directional change of a vehicle/projectile.

Environmental Conditions Tested:

- 10,000g Shock

- SEA™ Slave ASICs have been successfully tested from -65°C to +165°C

- SEA™ Bus Driver ASICs have been successfully tested from -55°C to +150°C

- 25kV ESD Test

- Accelerated Aging +70°C for 40 Days

- 5g RMS Random Vibration

Specifications

- Operating Temperature

-65°C to +165°C - Output

Tailorable, depending on device - Applicable Specifications

Can be part of complete systems that are compliant with:- MIL-STD-1901A Rocket Motor Ignition

- MIL-STD-1911A Hand Emplaced Ordnance

- MIL-STD-1316E Fuze Safety Criteria

- STANAG 4187, 4497 & 4368 NATO Equivalent Standard

- Flight Termination IAW RCC 319-10 Range Safety